Fraunhofer Institute has acquired a hot isostatic press (HIP) to improve its knowledge of pressure-supported heat treatment.

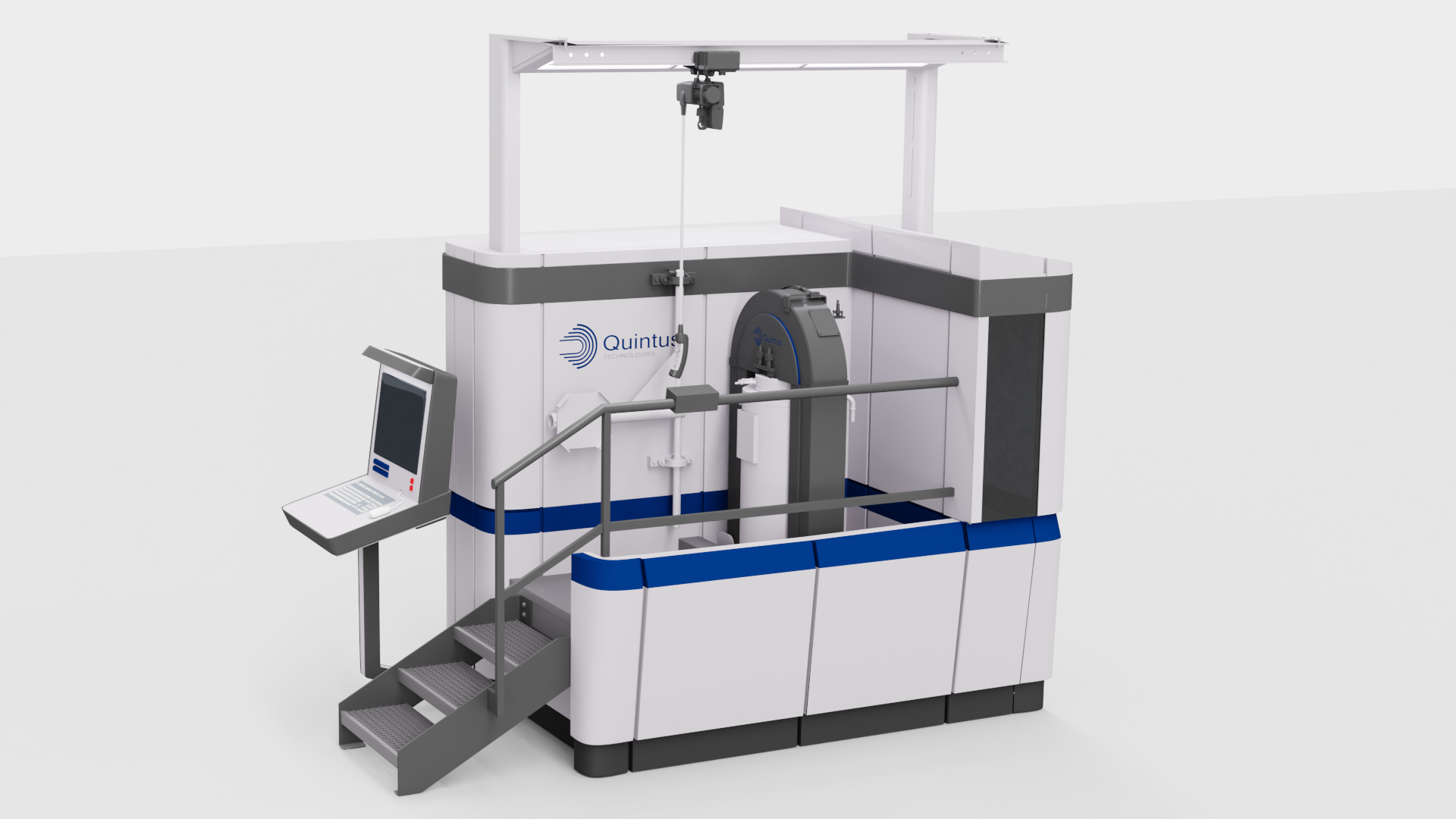

According to the institute, the Quintus Hot Isostatic Press QIH 15L will be used to research using combined processes, such as heat treatment and hot isostatic pressing (HIP), for materials such as nickel-based superalloys and intermetallic materials such as titanium aluminides.

The HIP incorporates a furnace chamber with a diameter of 170 mm and a height of 290 mm at a maximum pressure of 200 MPa and a maximum temperature of 1400 °C. The system is equipped with Quintus’ uniform rapid quenching (URQ) technology, which enables cooling rates of up to 10³K/min. This makes it possible to carry out multi-stage heat treatments in the actual HIP process.

Fraunhofer also reportedly plans to use the press with additive manufacturing (AM), improving existing HIP treatments and adapting them to 3D printing processes, which involve different microstructures than conventional manufacturing technologies.

The HIP process combined with the AM process could significantly save process time, the institute says.

This story uses material from Fraunhofer, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.