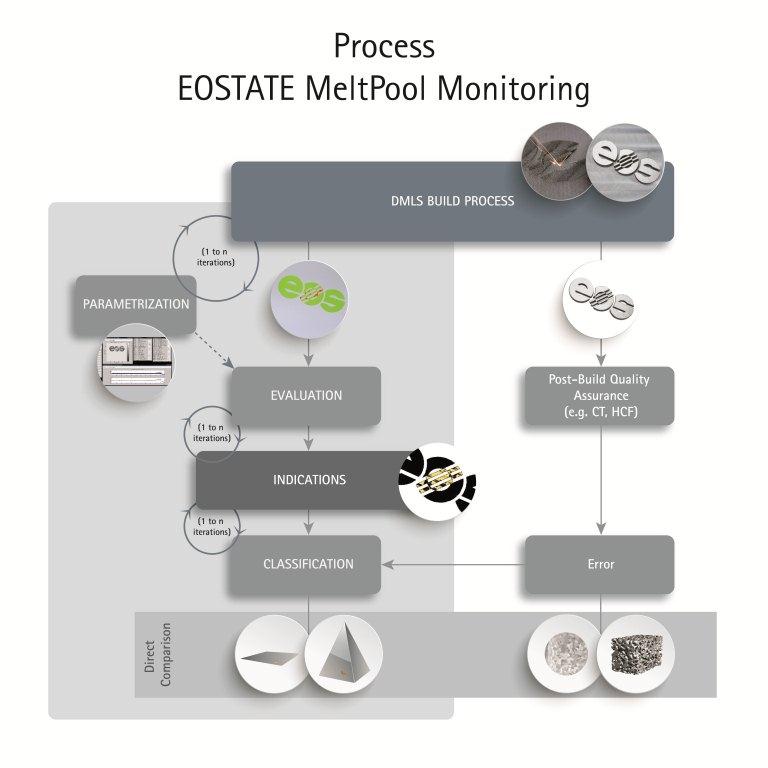

AM specialist EOS plans to introduce its EOSTATE MeltPool processing monitoring system to pilot customers, the company says. The system, which is an add-on to the EOS M 290 DMLS system reportedly improves part traceability and allows for an automated surveillance and analysis of the melt pool during the DMLS build process.

‘We consider the EOSTATE Meltpool monitoring system as an initial step for online control and part quality inspection,’ Said Semih Pilatin, Technology Programs Manager at TUSAS Engine Industries Inc, one of the pilot customers. ‘We are planning to use this tool for aerospace engine parts manufacturing where tight tolerances and high performance are expected. With this tool, we can capture potential part defects online at an early stage and with minimal effort to assess the part quality.’

This story is reprinted from material from EOS, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.