Barium titanate is an important electroceramic material used in trillions of capacitors each year and found in most electronics. Researchers at Penn State have now produced the material at record low temperatures, which could lead to more energy efficient manufacturing.

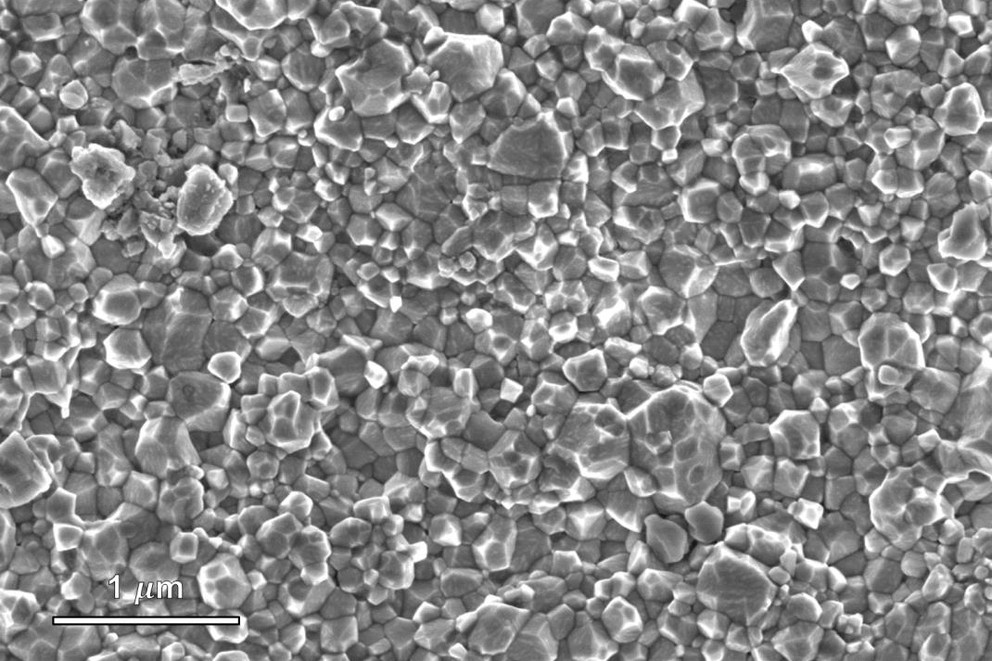

The researchers used a cold sintering process to densify barium titanate ceramics at less than 572°F (300°C), the lowest processing temperatures ever used, while maintaining the quality achieved by modern commercial manufacturing processes at higher temperatures. They report this work in a paper in the Journal of the European Ceramic Society.

"Our work is the first example showing we can densify ferroelectric oxides in a single step," said Kosuke Tsuji, a doctoral candidate in the Department of Materials Science and Engineering at Penn State and lead author of the paper. "It should open up the possibility to densify many more inorganic materials at low temperatures."

This is the first time that researchers have densified barium titanate in a single step using cold sintering. Previous attempts required secondary heating to produce materials with useful dielectric properties, said the researchers.

Sintering is a commonly used process to compress fine powders into a solid mass of material using heat and pressure. The cold sintering process, developed by scientists at Penn State, accomplishes this at much lower temperatures and shorter timescales than conventional sintering. According to the researchers, this emerging technology could reduce the costs and environmental impacts of manufacturing a wide range of materials.

The researchers used new chemistries to densify barium titanate in a single step. Cold sintering involves adding a few drops of liquid to ceramic powder. Reactions between moisture, heat and pressure then create denser materials than can achieved with heating at higher temperatures without liquid.

Previous cold sintering research used neutral or acidic solutions, but this new study incorporated hydroxide, an alkaline material. The hydroxide helped to produce barium titanate with the necessary dielectric properties at lower temperatures, the scientists said.

"This research shows that materials that were previously difficult to sinter can now be done," said Clive Randall, professor of materials science and engineering at Penn State, who led the development of cold sintering. "It takes us to the dream that we can eventually find the right chemistry to allow all ceramic materials, and maybe even metal materials, to be cold sintered."

Barium titanate is the basic compound used to produce high permittivity dielectric materials in multilayer capacitors. Of the more than 3 trillion ceramic capacitors produced each year, about 90% contain barium titanate.

"These devices underpin the modern electronic world," said Randall, who also serves as director of Penn State's Materials Research Institute. "The implications of applying this technology to barium titanate are enormous. In your cell phone alone, you may have 1000 components that are all made of barium titanate. It is ubiquitous to all electronics."

Lowering the temperatures used in commercial manufacturing would not only be more energy efficient but could also open the door to using less expensive metals and incorporating polymer composites into these capacitors. "This is very attractive to many of the leading capacitor companies, which are all working with these researchers through Penn State's Center for Dielectrics and Piezoelectrics (CDP)," Randall said.

This story is adapted from material from Penn State, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.