A new technology developed by researchers at Penn State, known as cold sintering process (CSP), provides an efficient way to combine incompatible materials, such as ceramics and plastics, into new, useful compound materials. It could also lower the energy cost of many types of manufacturing.

Ceramics are the oldest known man-made material, dating back tens of thousands of years. Throughout that time, nearly all ceramics have been made by heating ceramic powders to high temperatures, either by firing in kilns or sintering in furnaces, both of which require large amounts of energy.

"In this day and age, when we have to be incredibly conscious of the carbon dioxide budget, the energy budget, rethinking many of our manufacturing processes, including ceramics, becomes absolutely vital," said Clive Randall, professor of materials science and engineering at Penn State, who developed the process with his team. "Not only is this a low temperature process (room temperature up to 200°C), but we are also densifying some materials to over 95% of their theoretical density in 15 minutes. We can now make a ceramic faster than you can bake a pizza, and at lower temperatures."

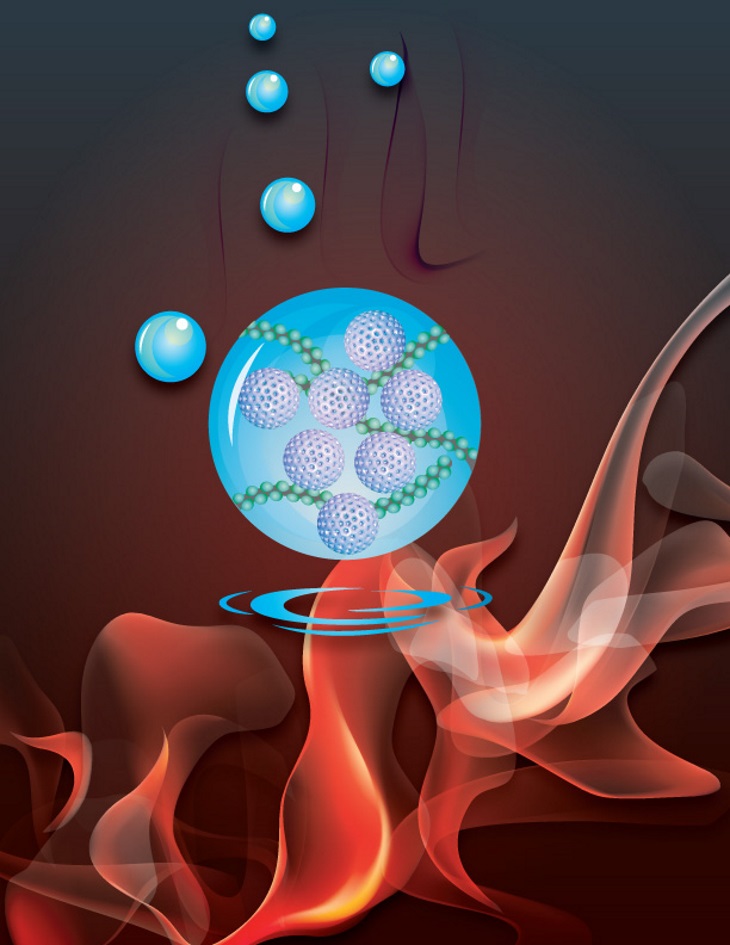

According to the researchers, the process involves wetting ceramic powder with a few drops of water or acid solution. The solid surfaces of the particles decompose and partially dissolve in the water to produce a liquid phase at the interface between the individual particles. Raising the temperature and pressure then causes the water to flow and the solid particles to rearrange in an initial densification stage.

In a second stage, clusters of atoms or ions move away from where the particles are in contact, aiding diffusion, which then minimizes surface free energy and allows the particles to pack tightly together. The key is knowing the exact combination of moisture, pressure, heat and time required to capture the reaction rates so the material fully crystallizes and achieves a very high density.

"I see cold sintering process as a continuum of different challenges," Randall said. "In some systems, it's so easy you don't need pressure. In others you do. In some you need to use nanoparticles. In others, you can get away with a mixture of nanoparticles and larger particles. It really all depends on the systems and chemistries you are talking about."

In a recent paper in Advanced Functional Materials, Randall and his co-authors describe using CSP to perform the co-sintering of ceramic and thermoplastic polymer composites. Three types of polymer were selected to complement the properties of three types of ceramic – a microwave dielectric, an electrolyte and a semiconductor – in order to highlight the diversity of applicable materials. The resultant composite materials demonstrated new possibilities for dielectric property design, as well as for ionic and electronic conductivity design. These composites can be sintered to high density at just 120°C in 15 to 60 minutes.

The Penn State team has also begun building a library of the precise techniques required to use CSP on various materials systems, with 50 processes verified to-date. These include ceramic-ceramic composites, ceramic-nanoparticle composites and ceramic-metals, as well as the ceramic-polymers discussed in the paper.

Other areas that are now open to exploration by CSP include architectural materials such as ceramic bricks, thermal insulation, biomedical implants and many types of electronic components. "My hope is that a lot of the manufacturing processes that already exist will be able to use this process, and we can learn from polymer manufacturing practices," Randall concluded.

This story is adapted from material from Penn State, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.