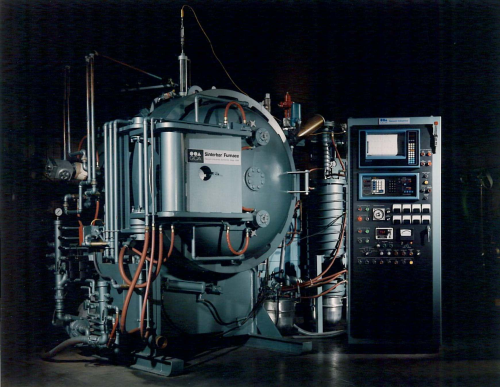

With help from renowned pressure furnace experts Fuad Barbar, the company has expanded the temperature range and pressure capabilities of the Sinterbar line it improved and improved its thermal performance, overall safety, durability and cost-effectiveness.

The new Sinterbar line has temperature capabilities of 1650°C or 2200°C, with pressures of 60 to 100 bar (900 to1500 psig). Standard sizes of 1, 4, 10, and 12 ft2 (28, 113, 283, and 340 lit) are available with optional debinding capabilities.

CVI Sinterbar furnaces are used to densify hardmetals and ceramic powder parts. After a part has been debound and sintered in the furnace it is further densified by introducing an inert gas static back pressure of up to 100 bar (1500 PSIG) at high temperature removing a majority of the remaining porosity. The process provides a finished part with almost 100% theoretical density and maximum mechanical strength. It is used primarily on hard metals like tungsten carbide and engineered ceramics.