Stringer presented a paper “Ongoing Investigation of Lubricant Transport within a Powder Metal Compact during Pre-Sinter,” along with the results of research and an accompanying white paper on the topic.

Modelling lubricant pressure

According to the research abstract, lubricants are a necessary component to the production of parts from PM to assist in the compaction and removal of the part from the compaction die. The added lubricant is then thermally diminished during the initial stage of the sintering process to help achieve desirable microstructure and physical properties of the part.

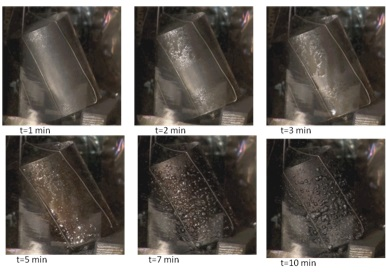

The presentation then demonstrated the project which applied metrics to the exit of the lubricant by way of mathematically modeling lubricant pressure and flow using a form of the Rideal-Washburn equation. Several conditions were considered for study including density, lubricant type, temperature, and atmosphere.

Experiments conducted by the team examined ideal lubricant removal systems, temperatures, atmospheres, and conditions for ideal delubrication that reduce or eliminate soot and carbon deposits and improve viscosity. The research also addresses variables in optimum de-lube time to part density.

To receive the full white paper, contact Stringer directly at craigstringer@atlaspressed.com