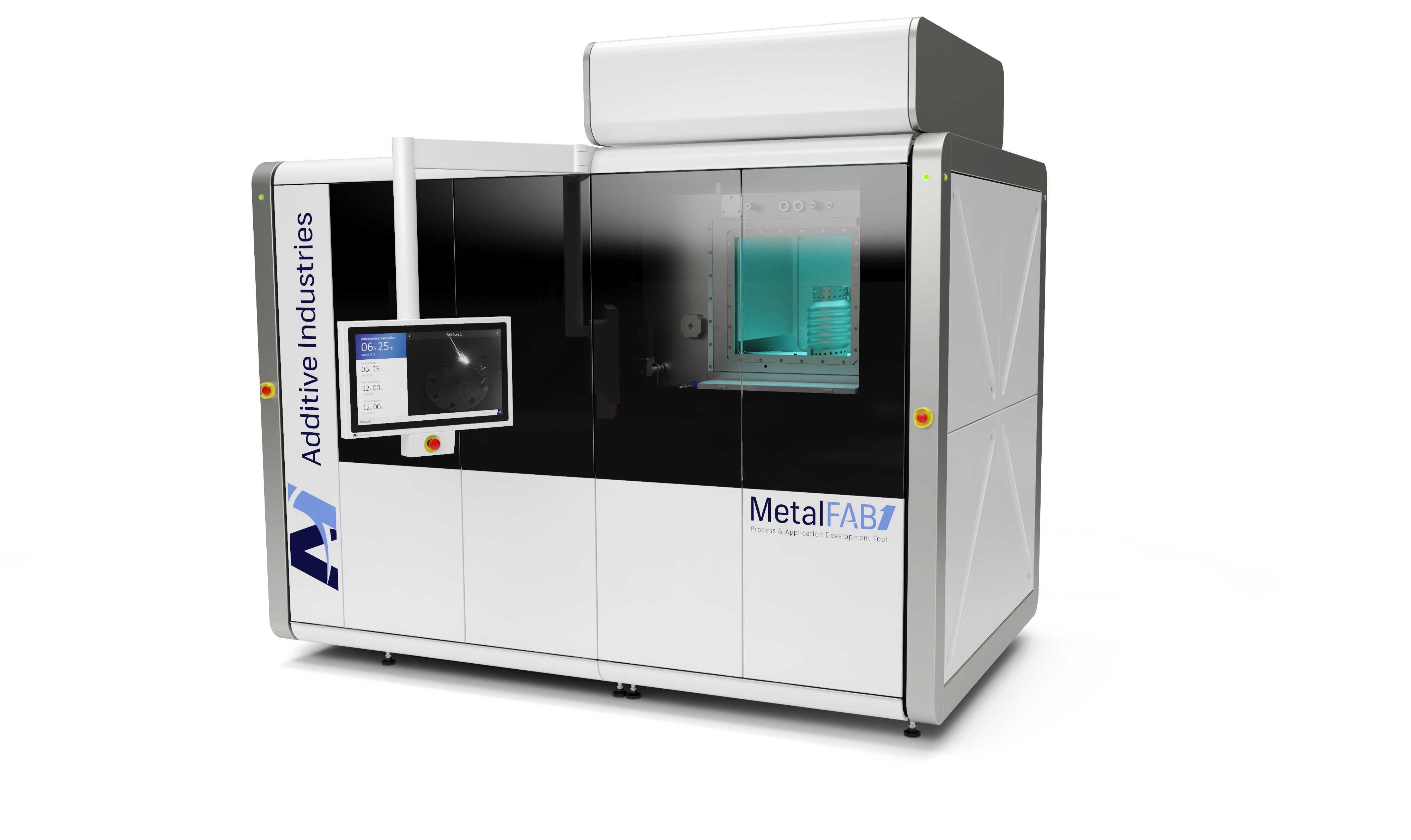

3D printing company Additive Industries says that a ‘prestigious aerospace company located in California’ has bought six of its MetalFAB1 additive manufacturing (AM) machines.

The order brings the installed base of MetalFAB1 systems to 10 with more possible in 2020, the company said.

The aerospace company was able to consolidate approximately 700 kilograms of powder in the month of June using the four laser MetalFAB1 systems it has currently in operation. It will now be able to produce a part of over 420 mm diameter by 400 mm tall parts weighing 180 kg, according to Additive Industries.

‘This part is likely the largest, most complex powder bed fusion part ever produced in series production,’ said Shane Collins, general manager for Additive Industries North America, Inc.

‘The fast growth in North America is partly due to our focus on the aerospace sector and the aeronautics adoption curve for production additive manufacturing,’ added Daan Kersten, CEO of Additive Industries. ‘We expect this growth to further accelerate when our customers publicly release their applications and more companies are able to visualize the large, complex parts that can be manufactured on the MetalFAB1 system in titanium, aluminum, steel and nickel-based alloys.’

This story uses material from Additive Industries, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.