UV coating technology offers a faster, smaller, and cleaner process for eco-conscious coating operations. Sustainable manufacturing processes have the following characteristics:

- Conserve natural resources

- Save energy or water

- Avoid toxic or other emissions

- Contribute to a safe, healthy environment

- Use products made from salvaged, renewable, or recycled material

Clearly, UV coating technology meets the criteria of the first four items previously listed. Major efforts are under way today to meet the last criteria and to drive production of raw materials from salvaged, renewable, or recycled materials.

UV is not only a sustainable technology but, more importantly, it is also an economic solution, critical for U.S. manufacturers today. The UV industry has a long history of promoting sustainable practices and continues to advance efforts that positively impact manufacturing and the industry’s contributions to environmental protection, economic performance, and the social well-being of the communities, customers, and consumers they serve. This trend will likely gain importance in today’s worldwide marketplace.

Sustainability and economics are critical together. In fact, they are mutually dependent on each other. Responsible manufacturers are always looking for new ways to be sustainable, but the competitive marketplace will not allow them to implement a new product or process unless it also makes economic sense. We refer to this as the “economics of sustainability” (Fig. 1).

UV technology provides manufacturers the economics of sustainability, which consists of the following:

Faster

- Faster Line Speed

- Faster Cure Time

- Faster Coating Optimization

Smaller

- Smaller Floor Space

- Smaller Work In Process

- Smaller Energy Consumption

- Smaller Maintenance Costs

- Smaller Capital Equipment Cost

- Smaller Quality Costs

Cleaner

- Zero VOCs/No HAPs/No NVPs

- Reduced Reporting

- Improved Health and Safety

The manufacturer is able to run its process at a higher line speed, which offers more production capability without additional allocated capital. In addition, the UV process offers the manufacturer the benefit of a cure time that is less than 2 seconds—which offers many benefits ranging from immediate handling to reduction in quality costs. Also, UV coatings can be 100% solids, meaning no evaporation or solvent content, which allows the manufacturer to utilize all of its coating (100% optimization).

From a production standpoint, UV offers the manufacturer the ability to implement a process that consumes a great deal less floor space, mainly by eliminating conventional heat ovens and conveyors. Work in process is virtually eliminated due to the instant cure properties of the UV process. With the elimination of ovens and additional conveyors, the result will be greatly reduced energy costs. Smaller capital equipment costs will also be a significant benefit due to less actual equipment required, typically in the range of 50–60%. Quality costs will be minimized due to coat, cure, and pack philosophy of UV technology, which allows for immediate inspection after cure.

UV technology is sustainable and offers significant environmental benefits, such as no VOCs, HAPs or NVPs. Typically, UV offers the manufacturer reduced reporting and a cleaner and safer work environment.

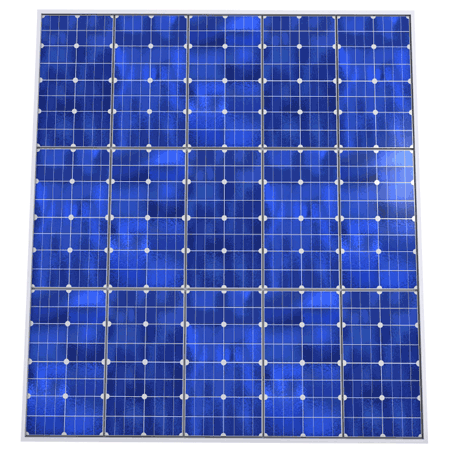

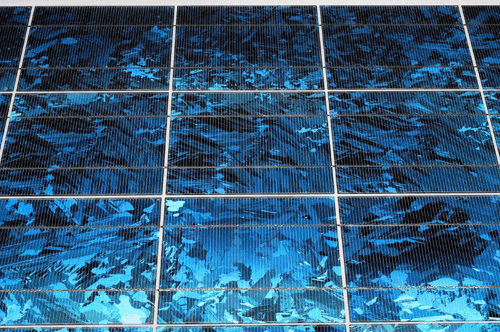

Case Study: Photovoltaics

Photovoltaics is rapidly growing in the U.S. and offers a great opportunity for implementing UV technology. UV technology is being employed for a variety of technical and economical reasons. Subsequently outlined are some examples of specific applications that are currently incorporating UV technology in their photovoltaic applications (Figs. 2 and 3).

- UV silver-conductive inks

- UV clearcoat

- UV dielectrics

As an example we have chosen UV-conductive silver inks. UV technology typically replaces solvent-based silver conductive inks and delivers sustainability, plus significant economic savings to the customer. These are both critical to a customer’s financial bottom line.

The subsequent outline is a cursory review of the economic benefits when applying UV technology to photovoltaic manufacturing.

Faster

Faster Line Speed

- Ability to run significantly more production

- UV-conductive silver ~40 feet/min

Faster Cure Time

- Eliminate conventional heat ovens

- No substrate damage or impact to end product

- Minimal heat impact to the substrate

Faster Coating Optimization

- No evaporation/curing in-process

- ~98% efficiency

- No set-up of materials in screen or flexo process/application equipment

Smaller

Smaller Floor Space

- Eliminate conventional heat ovens and related space

- Each square foot is dollars wasted

Smaller Work In-Process

- Almost no WIP/associated cost savings

- Eliminate in-process contamination

Smaller Energy Consumption

- Eliminate conventional heat ovens

- Save significant $$$$

- No need to use conventional heat ovens to cure a sustainable energy product

Smaller Maintenance Costs

- Less equipment/less maintenance

Smaller Capital Equipment Costs

- Less equipment means less capital investment $$$$ needed

Smaller Quality Costs

- Immediate inspection/less $$$$ waste

Cleaner

No VOCs/HAPs/NVPs

- Eliminates use of harmful chemicals

- Sustainable

Reduced Reporting

- $$$$ savings for fewer local environmental reports

Health and Safety Benefits

- Sustainable/better workplace environment

- Improvement for employees

Conclusions

Organizations with an eye on sustainability are realizing that embracing green practices can be a direct route to a successful, profitable business that adds value to manufacturers, their customers, shareholders, and the planet. Manufacturers must continue to implement sustainable technologies, but the success of any sustainable technology depends on the economic and financial returns to its operations. UV technology offers a definitive sustainable roadmap and delivers true economic savings.

For additional information, please visit www.RadTech.org and click on “sustainability.”

Bio

Mike Kelly is the president and CEO of Allied PhotoChemical, Inc., Kimball, Mich. He has held a variety of management positions, such as managing director Europe/Middle East/Africa, and president, Italia Operations, for Wonderware Corp., and sales manager at McNaughton-McKay Electric. Kelly served as global account manager, General Motors Corp., and held several other positions for Rockwell Automation/Allen-Bradley. Kelly received a master’s of finance from Walsh College; a master’s in management from Central Michigan University; and a BS in industrial engineering from Iowa State University.