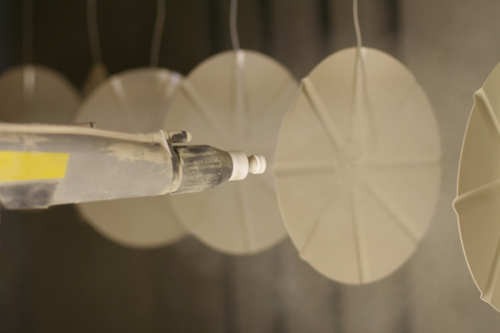

Powder coatings have become the finish of choice in industries ranging from heavy equipment to electronics and from outdoor recreational products to appliances. Key advantages that powder coatings have over liquid coatings include a solvent-free workplace, lower overall line costs and ease of cleanup. Powder coatings also can help finishers with their sustainability efforts, as they have zero to very low VOCs and offer overspray recycling capabilities and product waste that can generally be disposed of in conventional landfills (applicable regulations should be checked for proper disposal methods).Proper maintenance and spray techniques are essential to ensuring efficiency and effectiveness in any powder coating process. Falling into bad habits is easy and often goes unnoticed, but can result in efficiency losses and quality issues. And while supervisor benchmarking of operations is a great best practice for keeping a line running as smoothly as the day it was first installed, even the most productive powder coating lines can experience issues. When it comes to getting the most of powder coating, the issues listed below are not the only ones that need to be addressed but are certainly 10 of the most common. Proactively identifying potential problems before they occur can save time and money.1. A Well-Grounded RecommendationMost electrostatically sprayed powder coatings are given a negative charge out of the powder gun, while the part itself is grounded. This ground provides the opposite charge and attracts the powder to the part, but the part itself must be properly grounded for this to occur. A poor ground affects the transfer efficiency and results in improper film build. Proper maintenance practices can help to prevent this from occurring.For example, poor film build may be caused by “dirty” hooks — those insulated by powder buildup over time. The hooks must be kept clean — or replaced if they are beyond the point of being cleaned. The number of passes a hook can make after cleaning will vary. Periodic checks of the ground will help to determine the proper cleaning schedule.Also, good contacts must be maintained throughout the system. The conveyor line that the parts hang from should be separately grounded to ensure that proper ground gets to the part. Non-conductive contacts may develop as a result of poor maintenance practices, reducing or eliminating ground and thus preventing powder from being attracted to the part. To confirm proper resistance, a 500 volt megaohm meter should be used, and the resistance value should be < 1 megaohm. 2. More is LessThe key to quality powder coating is to spray just the right amount of powder with the minimum amount of air necessary. Excessive feed air pressure and powder volume will not result in faster or better coated parts, and generally speaking, the finish, the spray guns and the booth may be compromised as a result.If so much powder is being blown that the far end of the spray booth can’t be seen, it’s likely that too much powder is being conveyed through the gun. A typical powder gun utilizes an electrode at the end of the gun tip to emit negative ions into the air. The powder coating is then sprayed through the ion cloud that is created, developing the negative charge. When too much powder is sprayed into the ion cloud, or when it is sprayed at too high a velocity, the powder will not pick up a charge as efficiently and uncharged powder will drift around the booth (see Figure 1). A powder gun works most efficiently with an even, soft stream of powder coming from the gun nozzle – allowing the powder to pick up the proper charge and adhere to the part.While some wear on the pumps and spray gun parts is expected, blowing air at high velocity generally leads to premature wear and, potentially, impact fusion (fused grains of powder that fly from the gun as an already-cured mass that cannot be re-melted). System components and parts should be inspected regularly for wear and replaced when necessary to maintain efficiencies and finish quality. Powder supply lines to the guns should be free of kinks and have minimal bends. The gun should be cleaned at least as often as the manufacturer prescribes and potentially more often if operating under harsh conditions. The cost of properly maintaining equipment is far less than the potential losses that often result when maintenance is ignored. The desire to speed up a line and try to increase output must be tempered with the reality of the equipment’s capabilities. Optimal pressures can be set by regular consultation among the line’s applicators and technical service personnel from the powder coating and equipment manufacturers.3. Clean Air – Act!The importance of air quality to powder coating should not be underestimated. Many of the problems experienced in a powder coating spray installation can be directly traced to poor compressed air quality. Airborne moisture, oil and particulate matter such as dirt or dust have the greatest influence on air quality in the coating process. The presence of any contaminants can cause poor finish quality, a premature failure of cartridge filters, destruction of internal system components, poorly fluidized powder due to partially plugged fluidizing membranes and, potentially, a ripple effect of several of these concerns that will ultimately cause powder handling problems throughout the system.Compressed air, by its nature, may be moist and may contain oil. Depending on conditions, particulate matter may also be present. Quality air would constitute:

- Oil content of 0.1 ppm or less

- Dew point of 38 degrees Fahrenheit or less

- Particulate matter that does not exceed 0.3 microns in size

A desiccant air dryer and filter should be employed within the air delivery system to remove those elements before they reach the powder system. Regular audits of these air delivery components will ensure they can be replaced or replenished as necessary before impacting finish quality is compromised. 4. (Particle) Size MattersOne of the primary benefits inherent to powder coating is the ability to reclaim and reuse spray that does not adhere to parts. However, trying to coat with only reclaimed material is both inefficient and costly.

Every powder coating is manufactured to a particular size range. That same range needs to be maintained to ensure proper coating thickness, finish quality and transfer efficiency — regardless of whether it is virgin or reclaimed powder. Particles become smaller as they are continuously reclaimed and reused, which inhibits them from properly fluidizing and holding the proper charge. This can reduce transfer efficiency to 50 percent or less. Larger reclaimed particles, on the other hand, can cascade off the parts being coated, falling to the booth floor and resulting in a transfer efficiency of 30 percent or less. The best way to maintain the optimal particle size distribution is to constantly add virgin material into the system as reclaim is used to achieve the optimal transfer efficiency. Powder suppliers can help determine the correct virgin to reclaim ratio for the powder being used. 5. Don’t Get Mixed UpImproper color changeovers can lead to cross contamination that can, in turn, lead to rejected parts. Changing colors provides the opportunity to not only clean the entire system but also to ensure that spray guns and components are set up and operating properly. With certain types of powder products, there is more of a risk of contamination hazard than with others, as they may be highly incompatible with other powder products. Two different powder coatings may be incompatible due to various formulation differences such as resins, texturing, additives or other raw materials included in the formulation. For that reason, it may be advisable to have dedicated hoses for specific colors and/or textures to avoid contamination issues.General cleanliness is also often the root cause behind color contamination. Deferring upkeep until the entire booth and system components are covered, with excess powder on the floor, will generally result in inconsistent finish quality and/or color. Excess powder often leads to powder migration throughout the process area, enhancing the potential for color contamination as cleaning becomes more difficult. It may also cause powder to escape into the building’s air conditioning system, which can cause wear on these systems, create an unpleasant work environment, and present a poor physical appearance should customers visit the facility. 6. Treat ’em Right!Coating quality will only be as good as the quality of the surface to which it is anchored. Poor pretreatment practices may create adhesion, corrosion resistance and impact resistance problems on coated parts. There are varying pretreatment technologies available to finishers, each fitting specific needs. For example, pretreatment for an office desk would most likely not be the same as that for a bicycle frame. Knowing the pretreatment needs of each substrate is critical.Insufficient and/or inadequate pretreatment can lead to a number of issues, including:

- Loss of adhesion

- Pinholing/outgassing, resulting in small holes in the finish

- Laser edge issues, stemming from products cut with lasers and the resulting scale, which affects surface technology

- Flash rusting due to improper removal of surface oils

- Weld pullaway, in which powder will actually pull away from a weld

- Premature coating failure in harsh environments such as salt air

Applicators should work with their pretreatment and coating suppliers to ensure that the right pretreatment is in place when they make changes in the type(s) of product being coated, substrates, or in the coating technology used. In short, the coating is only as good as the substrate to be covered.7. The Price Is (Not) RightAll powder coatings are not the same. Purchasing only on price per pound and specific gravity is not a formula for real savings. Rather, it is better to understand the price per square foot covered, or the applied cost.Basing purchase decisions solely on price per pound and specific gravity ignores key performance and process standards, such as the coating’s durability, UV resistance, uniformity of particle size, or whether the powder coating contains fillers or off-specification resins. It also takes the batch-to-batch consistency out of the purchase decision, which is an important consideration in maintaining overall finished goods quality. Powder that varies in particle size greater than 10 microns can lower transfer efficiency and requires higher average film coverage on complex parts. The result: more pounds of powder required to coat parts. There is no set number for transfer efficiency, as this depends on what is being coated. Perhaps the best way of understanding the true cost is to ascertain the current transfer efficiency and determine the applied cost basis — not just the powder cost. Considering the applied product cost and overall performance at the recommended film thickness will allow finishers to see the true cost when making product choices.

8. The Ideal Forecast: Cool & DryAll powder coatings require a cool, dry storage environment. Ideal storage conditions are at temperatures below 80 degrees and humidity levels under 50 percent, and low-cure powder coatings may require even cooler temperatures. In locations prone to hot, humid conditions, air conditioned storage is a good option. Because powder coating is a hygroscopic material, it absorbs moisture readily. When exposed to excess moisture, the coating will have a tendency to cake. Storing the material in thick plastic bags is generally not enough, and air conditioned storage remains the best option in high-humidity areas. Powder stored in excessive heat may be damaged to the point where flow is inhibited. Extreme heat can cause powder to cure and fuse in storage, resulting in a sandpaper-like finish once applied. The higher the temperature, the faster such damage may occur.9. Follow the RecipeThere are really only three outcomes when it comes to curing the powder coating: the proper cure, under-curing, or over-curing, with temperature and time being the key variables in the process.Temperature pertains to the part being coated, not the oven temperature. For example, “10 at 400” means 10 minutes at 400?F metal temperature – not 10 minutes at 400?F oven temperature. The best way to verify the oven and part temperatures is to use an oven recorder to chart both the temperature of the part and the oven air. This should be done constantly, as conditions may change quickly. For example, a part may fall off the line and block air flow, resulting in a change of temperature. Establishing a temperature recording log is a wise practice to ensure quality finished part production.It is important to note that the full performance properties of the coating are achieved only when the film is properly cured. While proper curing is always the goal, under-curing is the next preferable outcome — instead of over-curing — as under-cured parts can be put back into the oven to achieve a full cure. Under-curing that is not addressed can result in poor adhesion, reduced impact resistance, poor gloss quality and reduced flexibility.Over-curing can result in discoloration, which may eliminate any opportunities to recoat and/or to apply any decals or pad print inks. Some powders can withstand double the time in terms of over-curing, but others are less forgiving. Every powder coating has a set cure schedule of time and temperature as recommended by the supplier. Powder coating suppliers can recommend a solvent rub test method that can be used to determine full cure on-line. 10. Formula for Success: QC + PMPowder coating success is highly dependent on an organization’s commitment to produce quality parts. Developing and adhering to a well-thought-out process that includes proper coating techniques is fundamental to that commitment. But the influence that quality control and preventive maintenance practices have throughout the organization should not be underestimated.Each coating process should have written performance specifications that include standards for performance, color, gloss and texture. By establishing a well-defined quality baseline, each and every employee throughout the process can easily identify inconsistencies, defects, and other concerns and quickly pull those rejected pieces. Preventive maintenance – including cleaning, inspecting, repairing and replacing components on a scheduled basis – is a leading indicator of powder coating success (see Figure 2). When repairs and replacements are needed, it is a wise investment to use only OEM-manufactured or -sanctioned spare parts or materials. Although lower cost replacements may be available, these knock-off or pirated parts might not be designed to the exacting standards of the manufacturer. Use of these parts may void warranties. Worse, use of non-approved components could lead to system failure or rejected parts — the cost of which can far exceed the savings on replacement components deemed “just as good.”Coatings line employees should be trained on how the overall coating system performs and the proper system maintenance. It is important that they recognize any variations or problems early on and understand that it is in everyone’s best interest to report issues as quickly as possible. Activity checklists are helpful in this regard, as some components and settings are best checked daily, while others will require weekly or monthly attention. Color change is another point when maintenance may be indicated. Establishing a method of operational consistency regarding maintenance helps employees understand what is expected of them.Conclusion - Perfect Powder CoatingEstablishing protocols and procedures for powder coating systems is a necessity to ensure a well-run, efficient operation; however, this need not happen in a vacuum. OEMs and finishers should look to coatings manufacturers to add value beyond product sales – offering expertise to save them time and money. From process solutions and improvements to equipment recommendations and engineering support, coatings manufacturers can provide customers with resources to help their powder coatings operations grow and thrive.For more information, please contact Bob Cregg at rpcregg@sherwin.comABOUT SHERWIN-WILLIAMS BUILDING PRODUCTSSherwin-Williams' Building Products Division offers a full assortment of production finishes to satisfy a wide range of variables relating to application, curing, finish durability, appearance, environmental requirements, "green" sustainability initiatives, and cost. This comprehensive lineup ranges from enamels and polyurethanes to powder coatings and coil and extrusion coatings.