To demonstrate compliance, manufacturers, importers, and distributors of aerosol coating products must calculate the product-weighted RF and show that it is within the rule limit. Users can rely on the information on product labels of compliant products, which should include the aerosol coating category code and the corresponding reactivity limit.

On June 23, 2009, the EPA amended the National Volatile Organic Compound (VOC) Emission Standards for Aerosol Coatings, primarily to add compounds to the regulated list (U.S. EPA 2009a). This so-called “aerosol coatings reactivity rule,” which was implemented in March 2008 (U.S. EPA 2008a), established national reactivity-based emission standards for the aerosol coatings category. There are 42 VOCs used in aerosol coatings that were regulated under the 2008 rule. The current amendment added 128 compounds to the regulated list, bringing the total number of VOCs to 170.

The entities that are regulated by the rule are manufacturers and importers of aerosol coating products and distributors whose names appear on the label of the products. Small quantity manufacturers (total VOCs used in aerosol coating products <16,500 lb per year) and manufacturers of products used exclusively outside of the United States are exempt.

Manufacturers are required to state the aerosol coating category code and the corresponding reactivity limit on product labels. Users of aerosol coatings can rely on the labels to identify compliant products. Users can also request reports submitted to the EPA by manufacturers on the VOC composition of the aerosol coatings and other information related to the reactivity limit calculation.

The EPA is currently engaged in the development of regulations for a number of industrial surface coating operations. Regulations under development (U.S. EPA 2008b) include the national emission standards for hazardous air pollutants (NESHAPs) and the national VOC rules. The NESHAPs1 are commonly called maximum achievable control technology (MACT) rules. Under the national VOC rules, the EPA issues control techniques guidelines (CTG) for some industrial operations in lieu of regulations to reduce VOC emissions. Some surface coating operations, such as automobile and light duty truck coating/manufacturing, are subjected to both MACT and CTG. The EPA plans to integrate the rule making effort to streamline requirements (U.S. EPA 2008b).

The aerosol coatings reactivity rule is part of the national VOC rule (U.S. EPA 2009b). It addresses the formulation of aerosol coatings, instead of application methods and emission controls when using the products. The rule aims to encourage reformulation of aerosol coatings to reduce ground-level ozone formation. Only manufacturers, importers, or distributors of aerosol coating products must comply with this national VOC rule. Note: This rule does not put any reporting or testing requirements on aerosol coatings end users. However, users of aerosol coatings who are required to calculate their emissions under MACT or CTG should be aware of potential changes in the VOC composition of the products. In addition to affecting calculated emission rates, such changes could, of course, also affect the durability or other properties of the coating.

In both the NESHAP and national VOC rule, emission limits are expressed in units of mass of VOCs per volume of coating solids deposited. The total mass of non-exempt compounds on the EPA’s HAP and VOC lists in a given product are summarized and reported as such. In the aerosol coatings reactivity rule, however, VOCs are first ranked by their reactivity in forming ozone. The emission limits, also called reactivity limits, are then expressed in mass of ozone produced per mass of aerosol coating product. This means that two aerosol coatings having the same total mass of VOCs can have different RFs, depending on their formulations.

The Ozone Problem

The Clean Air Act requires the EPA to control VOC emissions for the purposes of reducing ozone formation because ground-level ozone impacts human health and damages vegetation. Ozone is largely created by a photochemical reaction between nitrogen oxides (NOx) and VOCs in the presence of sunlight (Fig. 1). NOx and VOCs are, therefore, called ozone precursors. High ground-level ozone concentrations tend to occur in or downwind of urban areas on sunny summer days because sunlight and warm temperatures are favorable conditions for ozone chemistry. Ground-level ozone2 is a common air quality problem in urban areas because of ozone precursor emissions such as vehicle exhausts, fuel combustion, and solvent uses by industries.

Reactivity Matters

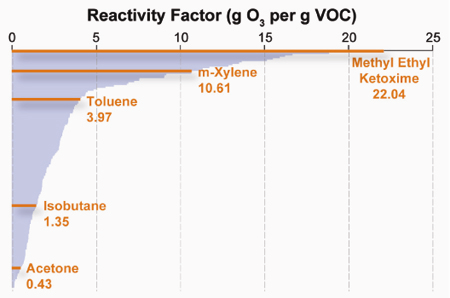

Not all VOCs are equally reactive. Some VOCs react slowly and have limited impacts on ground-level ozone. VOCs that are reactive lead to more ground-level ozone being formed than VOCs that are less reactive. The RF is measured in grams of ozone (O3) produced per gram of VOC. The 170 VOCs EPA listed in the current amendment have RFs that range from <0.01 g (e.g., benzaldehyde) to 22.04 g O3 per gram of VOC. For example, acetone has a RF of 0.43 g O3 per gram of VOC, whereas xylene has a RF of 10.6 g O3 per gram of VOC.

However, reactivity is not simply a property of the compound itself. The reactivity of a specific VOC varies with the amount of NOx and other VOCs in the atmosphere, and with meteorological conditions. The same amount of VOCs released to the atmosphere at different times or at a different location could result in a different amount of ozone being formed. The EPA determined that the RFs derived from the environmental conditions where ozone formation is most sensitive to changes in VOC emissions to be sufficiently robust for nationwide regulation. Figure 2 shows the range of RFs of all the regulated VOCs, with a few values highlighted.

Limiting the Reactivity

The goal of the EPA rule is to encourage aerosol coating product reformulation to lower the reactivity of VOC emissions. The EPA decided that reformulation to lower reactivity is a more feasible way to achieve VOC emission reductions rather than imposing emission controls, such as carbon adsorbers and thermal oxidizers, which would only apply to large industrial users. This is because most aerosol coatings are used in relatively small amounts by professionals and do-it-yourself consumers on an occasional basis. Together, these small-scale users account for 80% of the total sales.

EPA emission limits are product-weighted reactivity limits with units in grams of ozone per gram of aerosol coating product (Table 1). The six general aerosol coating categories have limits ranging from 1.2 g O3 per gram of primers to 1.90 g O3 per gram of metallic coatings. In addition, there are 30 specialty aerosol coating categories that have emission limits ranging from 0.60 g (pleasure craft topcoats) to 2.7 g (hobby/model/craft coatings, lacquer) O3 per gram of aerosol coating. These reaction limits are defined in the 2008 rule and are left unchanged in the current amendment to the rule.

| Aerosol Coating | Category Code |

Reactivity Limit (g O3 per g of aerosol) |

|

| 1 | Hobby/model/craft coatings, lacquer | HML | 2.7 |

| 2 | Aviation propeller coatings | APC | 2.5 |

| 3 | Polyolefin adhesion promoters | PAP | 2.5 |

| 4 | Slip-resistant coatings | SRC | 2.45 |

| 5 | Exact match finish—industrial | EFI | 2.05 |

| 6 | Aviation or marine primers | AMP | 2 |

| 7* | Metallic coatings | MCP | 1.9 |

| 8 | High-temperature coatings | HTC | 1.85 |

| 9 | Art fixtures or sealants | AFS | 1.8 |

| 10 | Corrosion-resistant brass, bronze, or copper coatings | CRB | 1.8 |

| 11* | Fluorescent coatings | FLP | 1.75 |

| 12 | Automotive bumper and trim products | ABT | 1.75 |

| 13 | Exact match finish—engine enamel | EEE | 1.7 |

| 14 | Floral sprays | FSP | 1.7 |

| 15 | Hobby/model/craft coatings, clear or metallic | HMC | 1.6 |

| 16 | Auto body primers | ABP | 1.55 |

| 17 | Vinyl/fabric/leather/olycarbonate coatings | VFL | 1.55 |

| 18* | Clear coatings | CCP | 1.5 |

| 19 | Exact match finish—automotive | EFA | 1.5 |

| 20 | Wood touch-up/repair or restoration coatings | WTR | 1.5 |

| 21 | Hobby/model/craft coatings, enamel | HME | 1.45 |

| 22* | Non-flat coatings | NFP | 1.4 |

| 23 | Glass coatings | GCP | 1.4 |

| 24 | Wood stains | WSP | 1.4 |

| 25* | Flat coatings | FCP | 1.2 |

| 26* | Primers | PCP | 1.2 |

| 27 | Ground traffic/marking | GTM | 1.2 |

| 28 | Pleasure craft primers, sufacers, or undercoaters | PCS | 1.05 |

| 29 | Spatter/multicolor coatings | SMC | 1.05 |

| 30 | Photograph coatings | PHC | 1 |

| 31 | Shellac sealers, clear | SSC | 1 |

| 32 | Weld-through primers | WTP | 1 |

| 33 | Shellac sealers, pigmented | SSP | 0.95 |

| 34 | Marine spar varnishes | MSV | 0.9 |

| 35 | Webbing/veiling coatings | WFC | 0.85 |

| 36 | Pleasure craft topcoats | PCT | 0.6 |

| *Six general coating categories. |

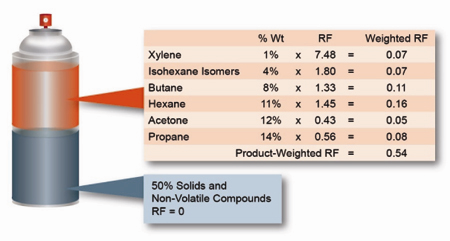

The product-weighted reactivity of an aerosol coating is simply the sum of the RF of each VOC multiplied by the weight fraction (Fig. 3). All 170 VOCs on the regulated list, including previously exempt chemicals,3 such as acetone and t-butyl acetate, that are present in an amount equal to or exceeding 0.1% must be accounted for in determining if the product meets the reactivity limit shown in Table 1. Any aerosol coating solid or ingredient that does not contain carbon is assigned an RF of zero. If a VOC is used in a product but is not listed in Table 1, manufacturers can petition the EPA to add the RF to the list. In the meantime, manufacturers should follow the procedure in §59.505(e) of the rule (U.S. EPA 2008a) to account for VOCs with unknown RFs.

Other Amendment Clarifications

The current aerosol coatings reactivity rule amendment also clarifies a few definitions. The EPA has a separate definition of VOCs (U.S. EPA 2009c) for determining compliance with emission limits for other sources. But for determining compliance with the aerosol coatings reactivity rule, regulated entities should include all 170 VOCs. In addition, the EPA provides a more detailed description of the division of responsibility between the certifying entity and regulated entity, and how the recordkeeping and reporting requirements will be met.

Test Methods

Facilities that manufacture aerosol coatings, handle the filling process, or distribute/import aerosol coatings must demonstrate compliance by calculating the product-weighted RF. Regulated entities can use either formulation data or analytical methods to determine the weight fraction of VOCs in their aerosol coatings. The two acceptable analytical methods are: 1) the California Air Resources Board’s (CARB) Method 310–Determination of Volatile Organic Compounds in Consumer Products and Reactive Organic Compounds in Aerosol Coating Products (CARB 2005), and 2) EPA’s Method 311–Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (U.S. EPA 2007). It is necessary for regulated entities to have one of these test methods in place to verify the accuracy of the formulation data.

Implementation Cost Analysis

Significant progress has already been made in reformulating aerosol coatings to meet EPA limits. CARB conducted a survey in 1997 to gather sales and formulation information from aerosol coating manufacturers in California. Based on that survey, the EPA believes that approximately 50% of all of the coatings were already meeting the emission limits in 1997. The EPA estimated the total nationwide cost of the final rule would be about $20 million. This includes the cost of the raw materials that the manufacturer will use to formulate coatings, the cost of research and development, and the cost of recordkeeping and reporting. The EPA’s cost estimate is sensitive to the percentage of aerosol coating products already meeting the limits since CARB’s reactivity limits became effective in 2002.

Regulation Impacts

The EPA estimated that this rule will reduce nationwide VOC emissions from the use of aerosol coatings by an estimated 17,130 tons, or about 19% of the 1990 baseline. However, the actual reduction of VOCs is likely to be far lower because many manufacturers already sell aerosol coatings that are in compliance. The actual reduction is estimated to be closer to 3,100 tons, or about 3.5% of the 1990 baseline. The effectiveness of this rule in reducing high ozone days depends on whether the reduction occurs in areas where ozone formation is sensitive to VOCs. The EPA believes some additional benefits to human health and the environment will come from the replacement of reactive VOCs that are also HAPs, such as toluene and xylene.

On the other hand, the EPA also recognizes the potential for small increases of ground-level ozone to occur in areas downwind from urban centers. This is because VOCs with lower reactivity have a longer lifetime in the atmosphere and can exert their impacts for a greater distance when they are carried downwind. The EPA did not perform nationwide modeling specific to this rule to quantify this potential impact, but based on research performed thus far, the EPA concluded that ozone reduction in urban areas outweighs the small increases in downwind ozone.

Notes

- Some VOCs are also listed as hazardous air pollutants (HAPs), such as toluene and xylene.

- Ground-level ozone is characterized as “smog”; this should not be confused with the depletion of ozone in the upper atmosphere 9−30 miles from the earth’s surface.

- Acetone and t-butyl acetate have relatively low reactivity factors (0.43 and 0.20 g O3 per gram of compound, respectively; see Fig. 2), so does ethane (0.31 g O3 per gram of compound), which was the baseline the EPA used to determine exemption.

References

U.S. EPA. 2009a. National volatile organic compound (VOC) emission standards for aerosol coatings. 74 FR 29595 40 CFR Parts 51 and 59. Final Rule: June 23, 2009. Docket EPA-HQ-OAR-2006-0971 #70.

U.S. EPA. 2009b. Information for consumer and commercial product study–Section 183(e) VOC rules. Available at: www.epa.gov/ttn/atw/183e/gen/183epg.html. Last updated August 19, 2009. Accessed Sept. 11, 2009.

U.S. EPA. 2009c. Definition of volatile organic compounds (VOCs). Available at: www.epa.gov/ttn/naaqs/ozone/ozonetech/def_voc.htm. Last updated March 31, 2009. Accessed July 28, 2009.

U.S. EPA. 2008a. National volatile organic compound (VOC) emission standards for aerosol coatings. 40 CFR Parts 51 and 59. Final Rule: March 24, 2008. Docket EPA-HQ-OAR-2006-0971 #45.

California Environmental Protection Agency Air Resources Board. ARB Method 310–Determination of the percent of weight of volatile organic compounds (VOC) in consumer products, antiperspirant and deodorant products, and aerosol coatings products. Available at: www.arb.ca.gov/testmeth/cptm/cptm.htm. Last updated May 5, 2005. Accessed July 28, 2009.

U.S. EPA. 2007. Method 311–Analysis of hazardous air pollutant compounds in paints and coatings by direct injection into a gas chromatograph. Available at: www.epa.gov/ttn/emc/methods/method311.html. Last updated August 7, 2007. Accessed July 28, 2009.

Bio

Wanyu Rengie Chan is a senior scientist in Exponent’s environmental and earth sciences practice. She advises clients on indoor and outdoor air quality, and greenhouse gas emissions. She has performed onsite sampling and computer modeling to evaluate potential human health and environmental impacts from airborne pollutants. Prior to Exponent, Chan conducted research at Lawrence Berkeley National Laboratory to develop a model that predicts indoor concentrations in homes and commercial buildings in the event of an outdoor chemical release. She holds a PhD in environmental engineering from the University of California at Berkeley.