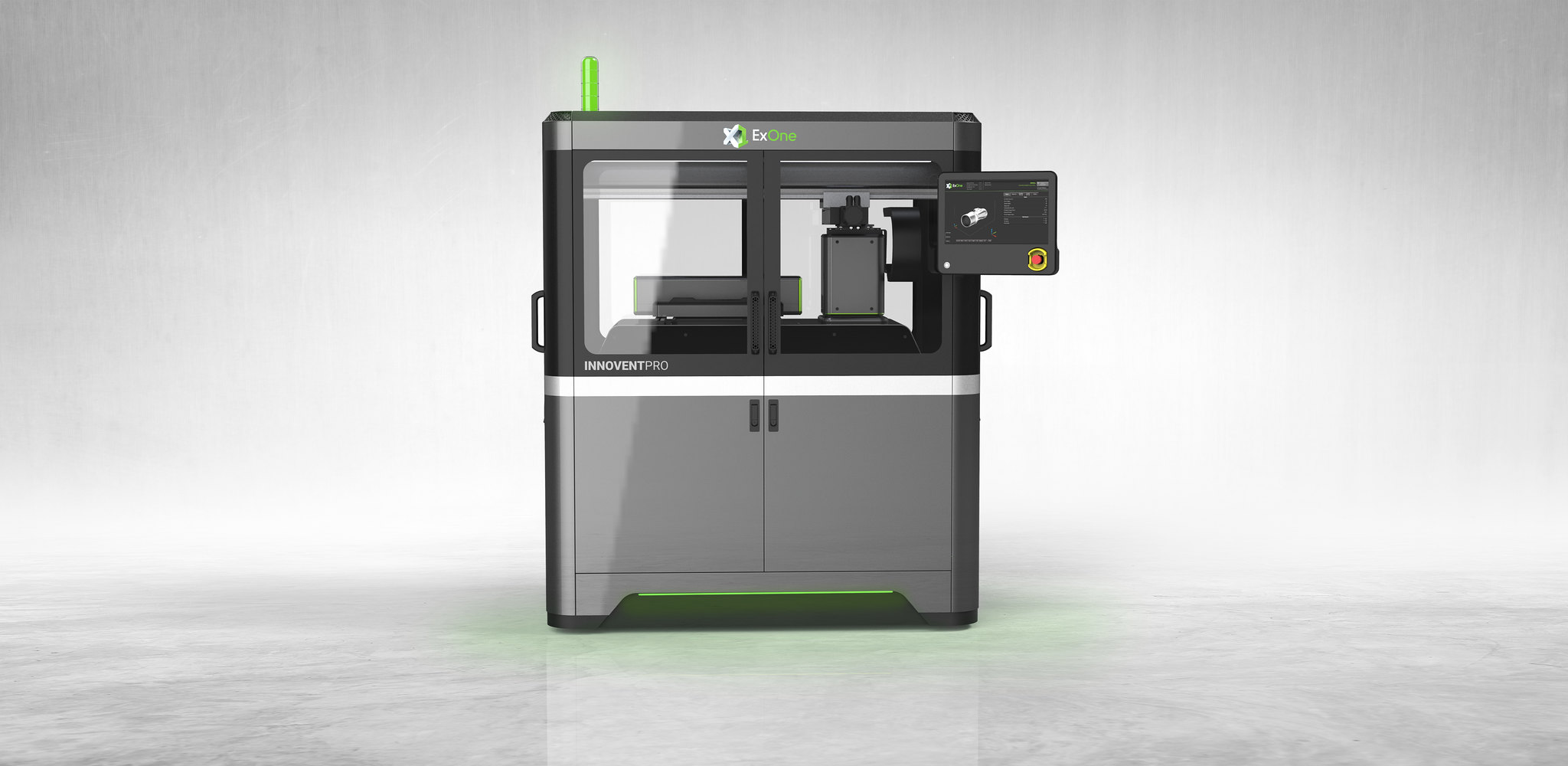

ExOne has released information about the InnoventPro, a planned binder jetting machine for the 3D printing of metals, ceramics and composites.

According to the company, InnoventPro is an upgrade of its Innovent+ metal binder jetting system. The InnoventPro has two new build sizes, a 3-liter and a 5-liter, with print speeds reaching 700 cc/hour.

The updated system is aimed at academics, researchers, and manufacturers, from machine and metal injection molding (MIM) shops to high-volume producers, ExOne said.

Binder jetting uses a digital file to inkjet a binder into a bed of powder particles creating a solid part one layer at a time. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

ExOne says that the machine features its new inkjet-printable nanoparticle suspension binders. Because nanoparticles can fill in the interstices between powder bed particles and can bond at lower temperatures, they enable stronger green parts, the company said. This can enable 3D printing of larger parts and finer features, delivering sharper corners and edges. The binders can also reportedly improve the resolution and sinterability of high-demand metals, such as copper and aluminum.

This story uses material from ExOne, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.