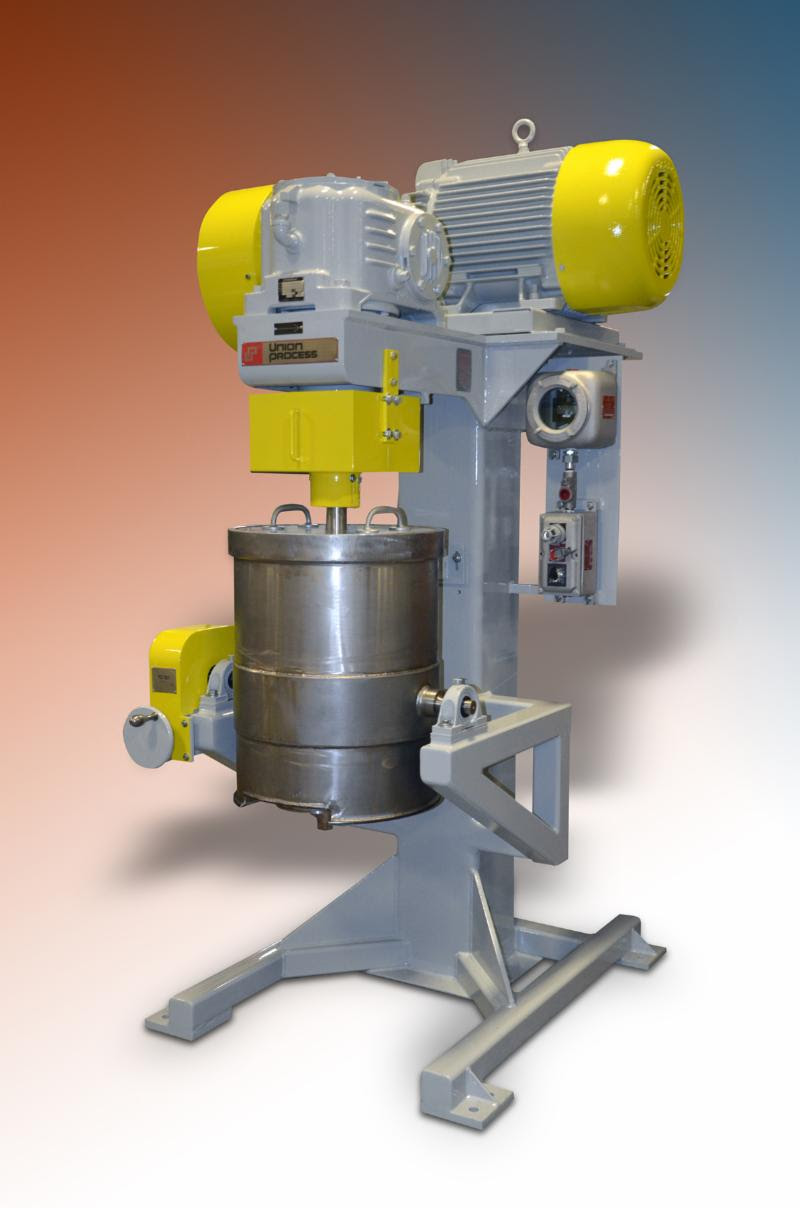

Union Process Inc, which specialises in particle size reduction and dispersing equipment has built a new grinder for its in-house pilot plant.

The Attritor features a frame to accommodates two tanks constructed of stainless steel. The mill has an explosion-proof motor and uses a remotely mounted variable frequency (inverter) drive. On the Attritor, there are stop/start push buttons with a potentiometer for controlling the speed.

‘This versatile design provides us with an opportunity to quickly and easily switch between S-10 Attritor and S-15 Attritor tank assemblies,’ said Chuck Major, sales manager. ‘Additionally, the S-10/15 Attritor can be configured for wet, dry, inert atmosphere or cryogenic milling.’

This story is reprinted from material from Union Process, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.