Sandvik’s new titanium powder plant and additive manufacturing (AM) operations in Sandviken, Sweden have reportedly received an AS9100 Revision D certification to make parts for the aerospace industry.

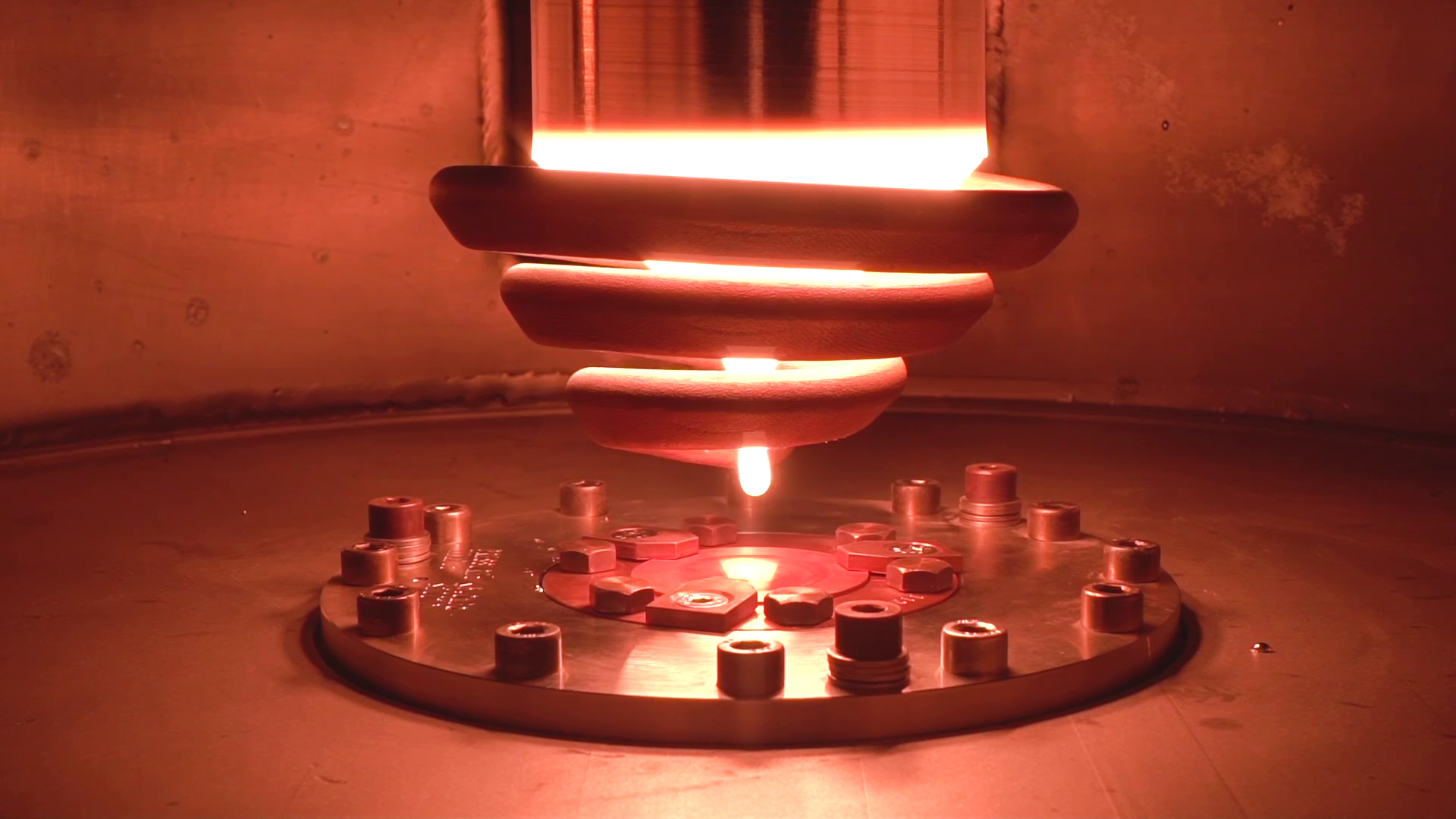

According to the company, the use of titanium powders for AM can reduce material waste and increase design freedom. The first two powders produced at the plant will be Osprey Ti-6Al-4V Grade 5 and Osprey Ti-6Al-4V Grade 23. In addition to the AS9100D certification, the plant is also certified according to ISO 9001, ISO 14001 and ISO 45001, Sandvik said.

‘With the AS9100D certification together with all our experts in materials, metal powder and additive manufacturing, we can now help our customers succeed in this high-growth area,’ said Kristian Egeberg, president of Sandvik AM.

This story uses material from Sandvik, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.