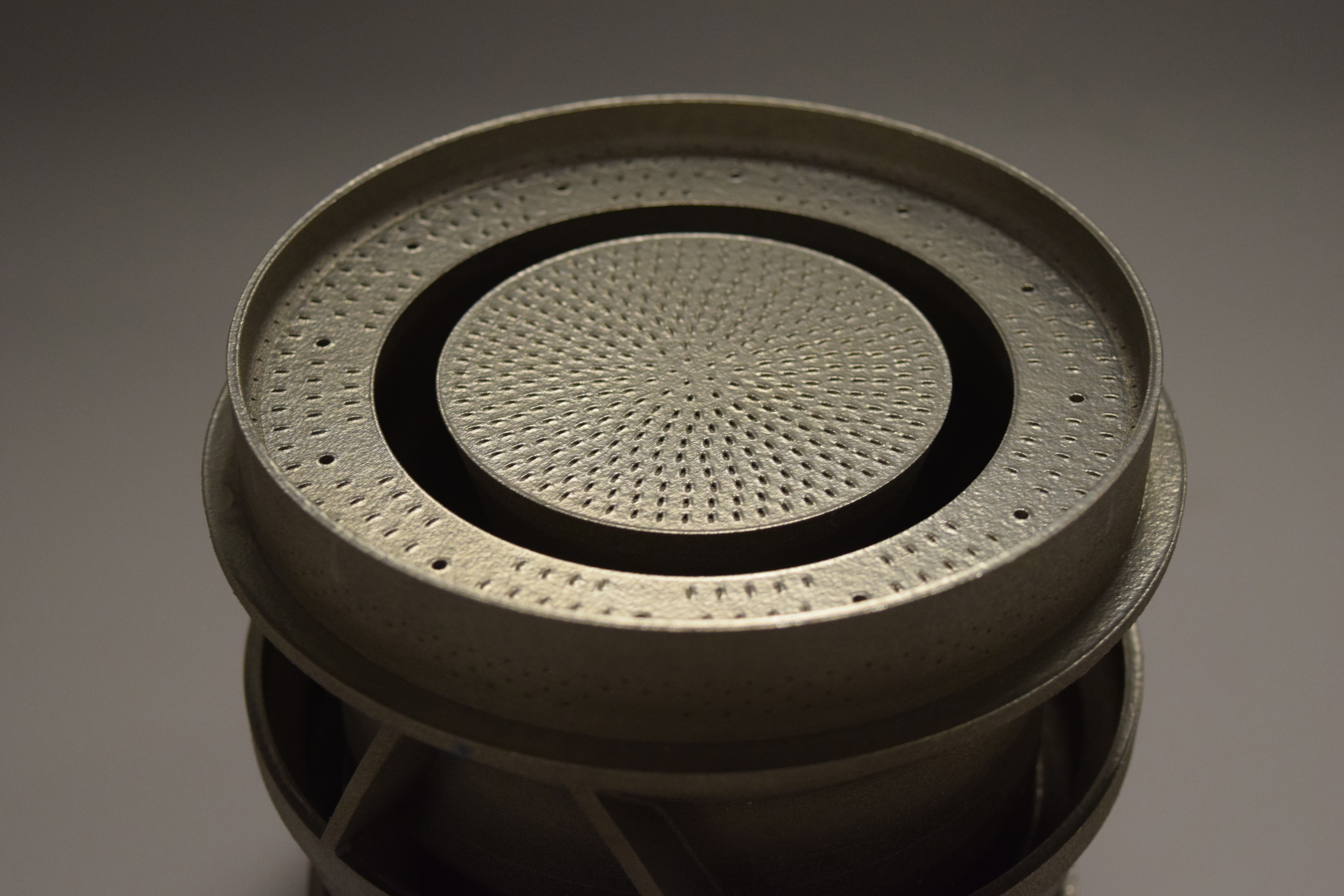

Siemens says that it has successfully 3D-printed and engine tested a dry low emission (DLE) pre-mixer for its SGT-A05 aeroderivative gas turbine.

The DLE pre-mixer is a complex component with over 20 parts involved in the casting and assembly using traditional manufacturing methods. By using nickel alloys as the additive manufacturing (AM) printing material, the 3D printed component requires only two parts and lead time is reduced by approximately 70%, the company says. 3D printing the DLE pre-mixer reportedly allows Siemens to simplify the production process, reduce external dependencies in the supply chain, and improve the geometry of the component.

This story is reprinted from material from Siemens, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.