Auto manufacturer DS Automobiles has used titanium additive manufacturing (AM) to develop new parts for its DS 3 Dark Side limited edition car.

According to EOS, which provided its EOS M 290 machine and EOS Titanium Ti64 material, while 3D printing is commonly used in the automotive sectors for prototyping, serial production with AM is still very rare, especially for metal parts. The EOS M 290 reportedly enables the production of 200 parts per build job.

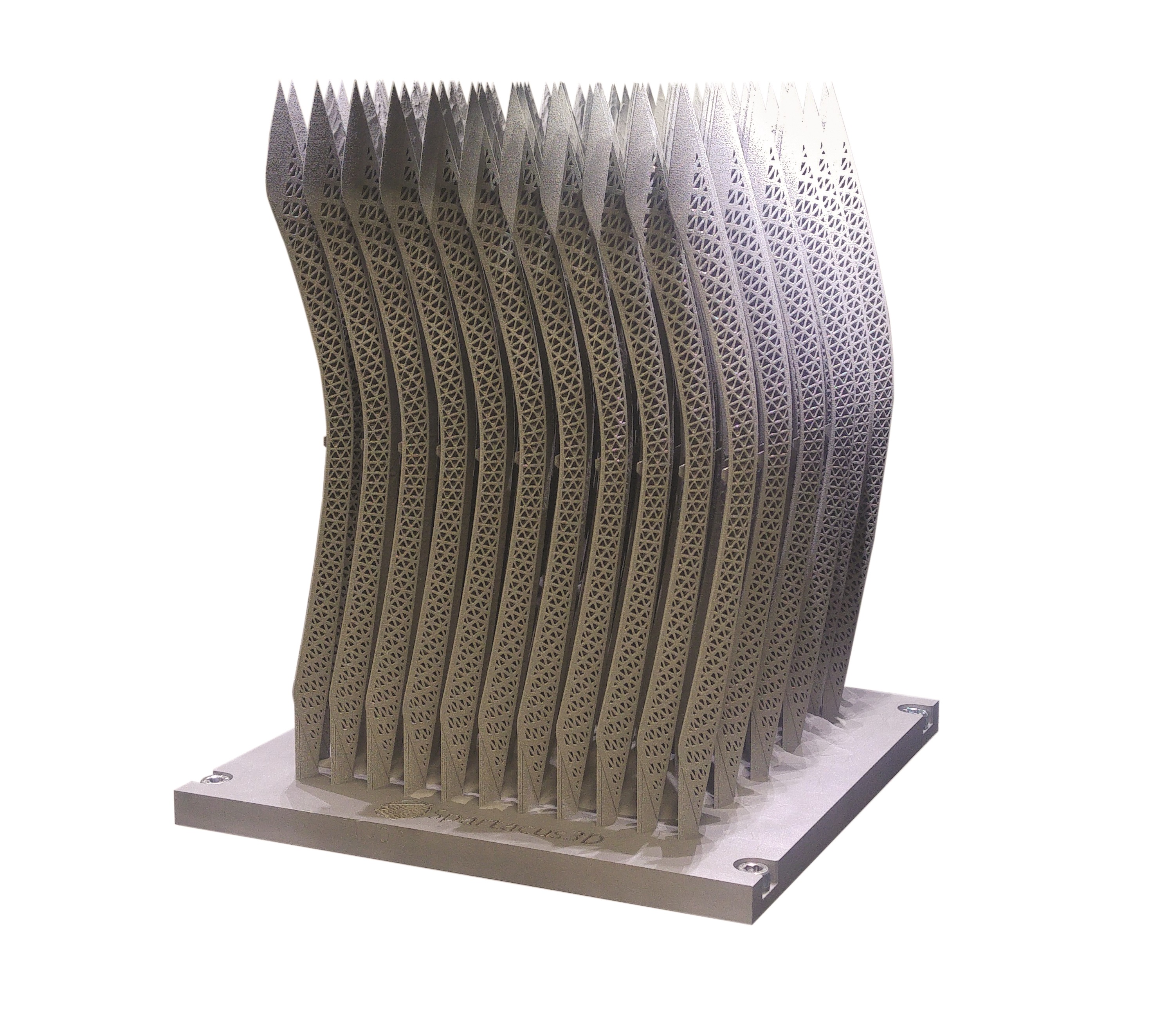

The DS design team used a parametric design to create the inside door handle covers and the electronic key holder detail in an intricate titanium mesh, covered with a matte finish obtained by manual polishing.

This story is reprinted from material from EOS, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.