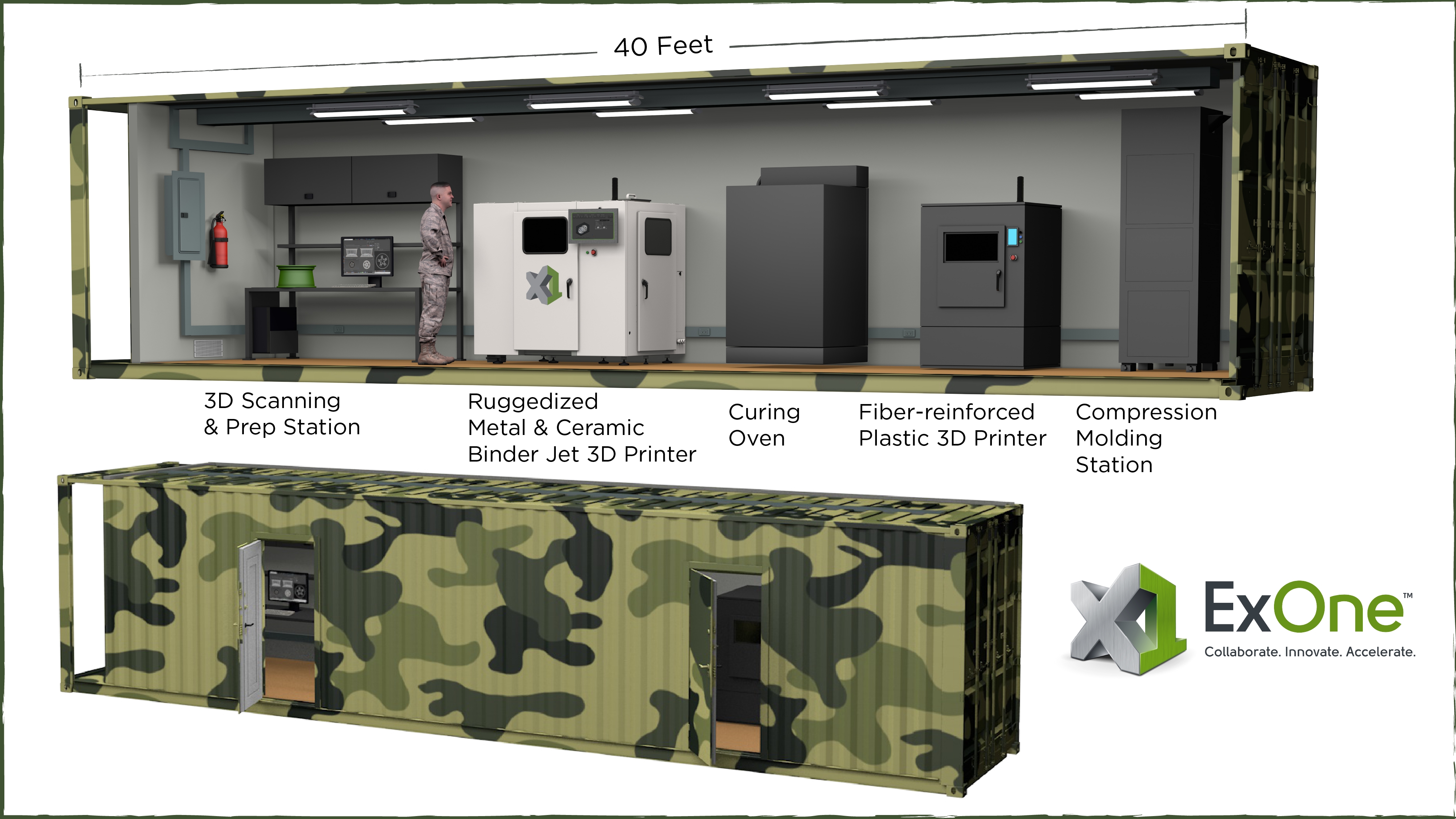

ExOne has been awarded a US Department of Defense contract to develop a self-contained 3D printing ‘factory’ housed in a 40 ft shipping container.

According to the company, the additive manufacturing (AM) system would be used directly in the field to manufacture parts to support military needs, disaster relief, or other remote opera-tions.

The US$1.6 million contract will focus specifically on improving the ruggedness of ExOne’s com-mercially available binder jet 3D printers for a range of operating conditions while maintaining final part quality, ExOne said. There are also plans to simplify use of the technology in the field with software and training.

The company is also developing a military version of its 3D printer that can 3D print 20 or more metal, ceramic and other powder materials into direct final products or tooling. Ideally, military personnel would 3D print a digital file of a broken or damaged part and have a finished product in less than 48 hours without conventional tooling in the self-contained pod. When a digital file is not available for older parts, the item can easily be 3D scanned and printed in the field.

This story uses material from ExOne, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.