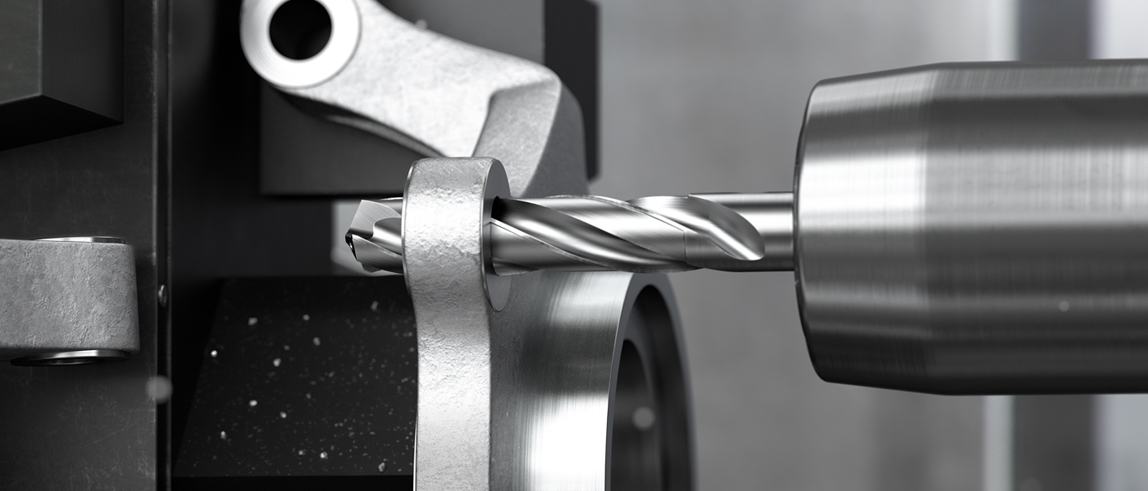

Sandvik Coromant has developed two new drills for drilling aluminium automotive parts. CoroDrill 400 and CoroDrill 430 can be used for the machining of components in medium-to-large volumes and are supported by CoroTap 100, 200, 300 and 400 taps.

‘Automotive manufacturers are increasingly adopting aluminium parts to help reduce vehicle weight and improve fuel efficiency,’ said Aaron Howcroft, Global Product Manager at Sandvik Coromant.

The two drills are available in the company’s N1BU solid-carbide grade, and CoroDrill 400 can also be produced using the new N1DU veined polycrystalline diamond (PCD) grade. N1DU provides PCD across the entire cutting edge, and due to PCD’s low coefficient of friction and high conductivity of heat, the tool’s cutting edges are less susceptible to built-up edge (BUE), Sandvik says. Sandvik Coromant recommends the use of the solid-carbide grade when the hole count is low and handling risk is high, while the PCD grade is preferable where hole count is high and higher productivity is required. CoroDrill 400 is recommended for drilling into solid material, as it features more flute volume for better chip evacuation.

This story is reprinted from material from Sandvik Coromant, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.