Quintus Technologies has delivered what it says is the world’s fastest fan-driven hot isostatic press (HIP) to a new company that focuses on postproduction of 3D printed metal parts.

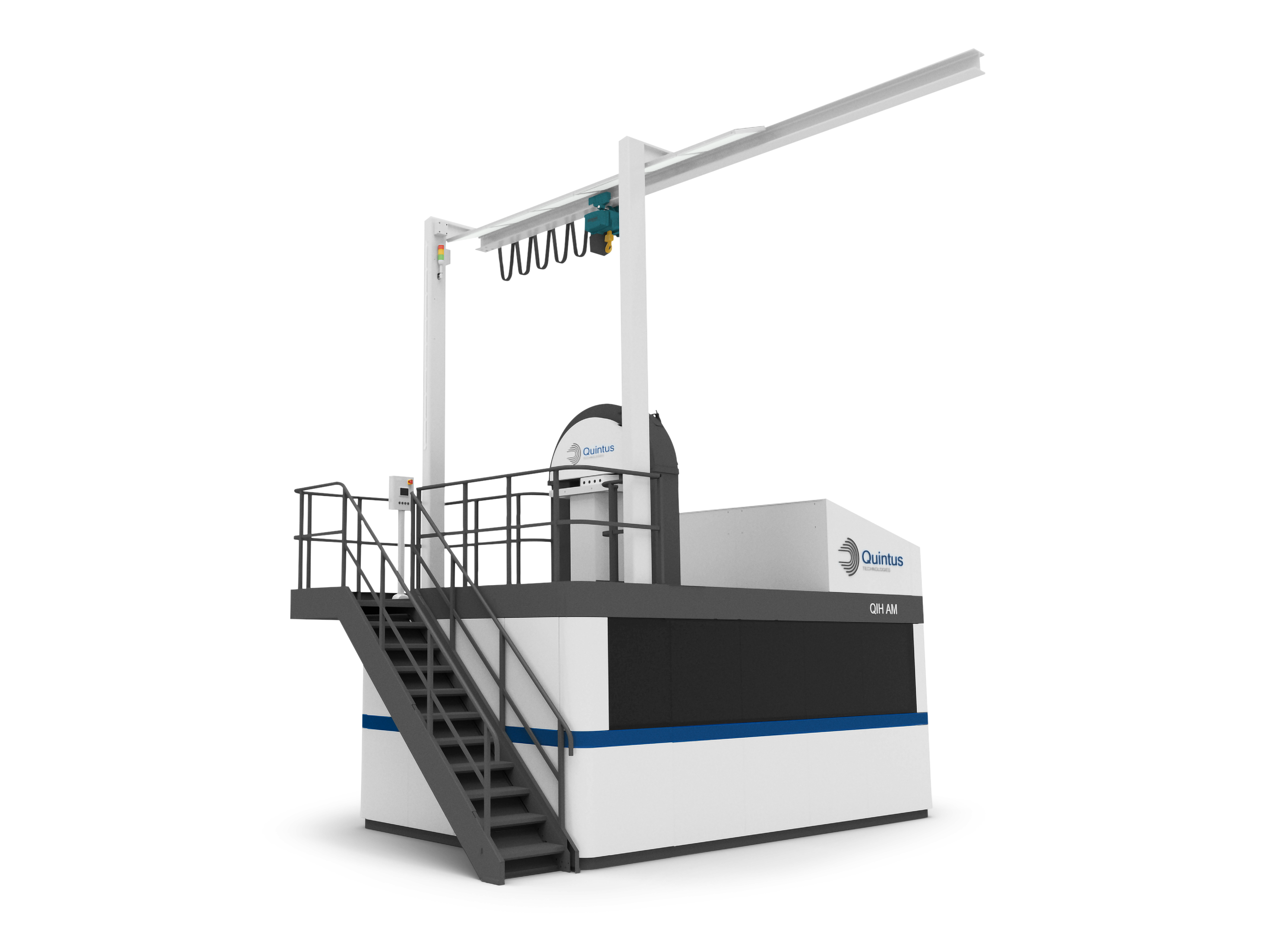

Italy-based PRES-X installed the QIH 60 M URC model which was especially designed for additive manufacturing (AM), according to Quintus. It features a hot zone of 16.14 x 39.37 inches (410 x 1,000 mm) and operates at a maximum temperature of 2,552°F (1,400°C) and maximum pressure of 207 MPa (30,000 psi), with a maximum workload weight of 1,322 lbs (600 kg). The HIP can achieve a cooling rate of 1500K/minute can be achieved while minimizing thermal distortion and non-uniform grain growth, producing finished 3D printed parts with improved material properties, the company said.

‘Our vision is to become the innovation leader within HIP,’ said PRES-X CEO and founder Andrea Scanavini. ‘We need a technical partner that shares our mission to be at the forefront, and Quintus is a perfect match. They have the same approach to introducing disruptive innovations in the field of HIP and HT, in the critical phases of post-processing AM parts.’

According to Scanavini, PRES-X currently focuses on the aerospace, space, defense, racing and automotive, packaging, and medical device markets.

This story uses material from Quintus, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.