Desktop Metal has launched Studio System 2, an ‘office-friendly’ metal 3D printing technology suitable for printing in low volumes for pre-production and end-use applications.

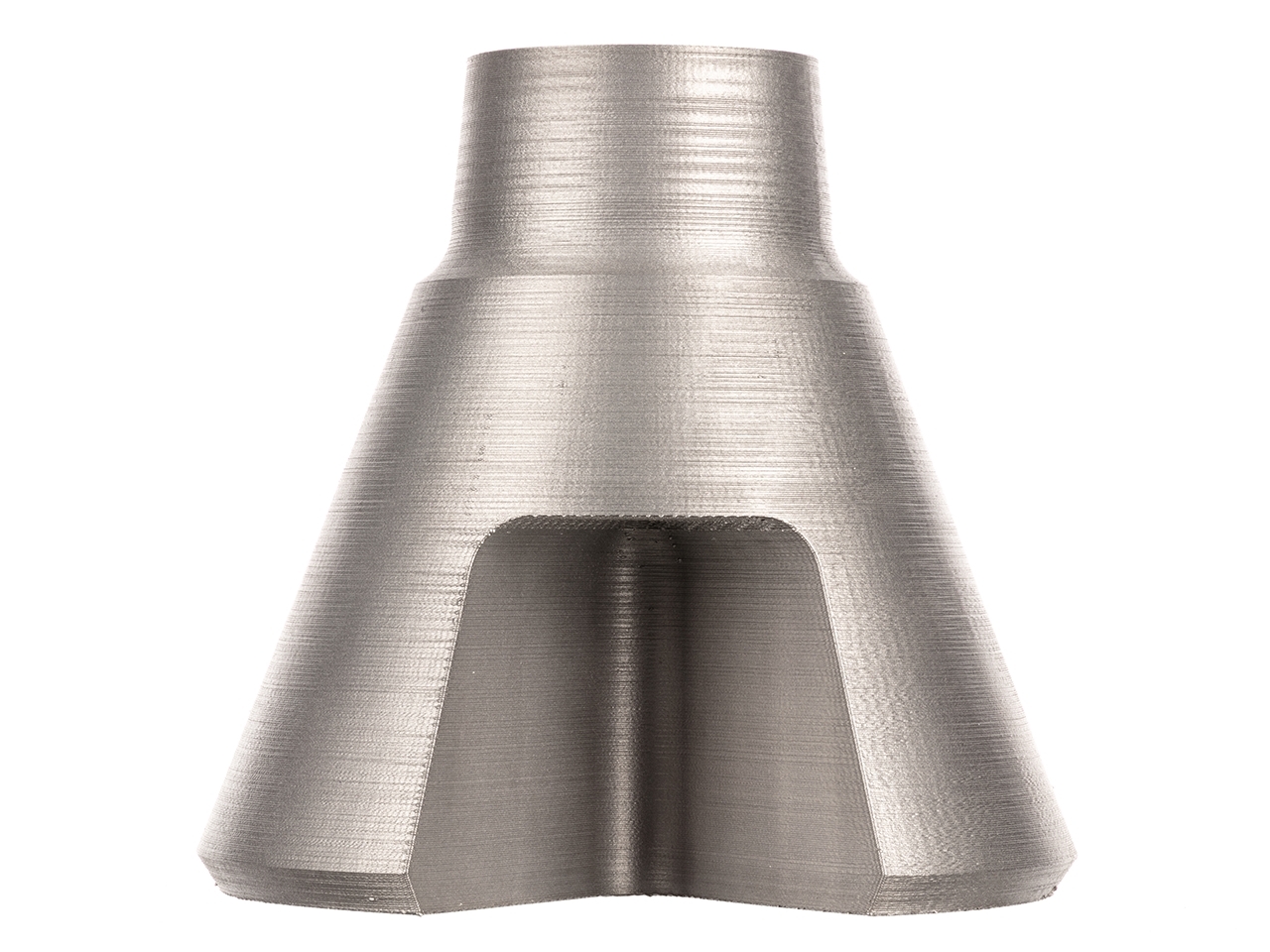

The machine is a new version of the Studio System, which was first launched in 2017, and uses Desktop’s bound metal deposition (BMD) technology, a powder metallurgy-based process that uses bound metal rods to shape parts layer-by-layer, rather than loose powder and lasers.

Studio System 2 also features new material formulations that allow parts to be transferred directly from the printer into the furnace in a more hands free experience, new print profiles and a re-engineered interface layer material for more even shrinkage during sintering and increased part success across an array of geometries, Desktop says.

The new printer also incorporates a heated build chamber and isotropic triply periodic minimal surface (TPMS) infill. Vacuum sintering in the furnace cam reach temperatures of up to 1400°C, according to the company.

The Studio System 2 has been launched with 316L stainless steel and is backwards-compatible through the use of a debinder with all materials previously supported by the Studio System, including 17-4PH stainless steel, 4140 low alloy steel, H13 tool steel, and copper.

This story uses material from Desktop Metal, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.