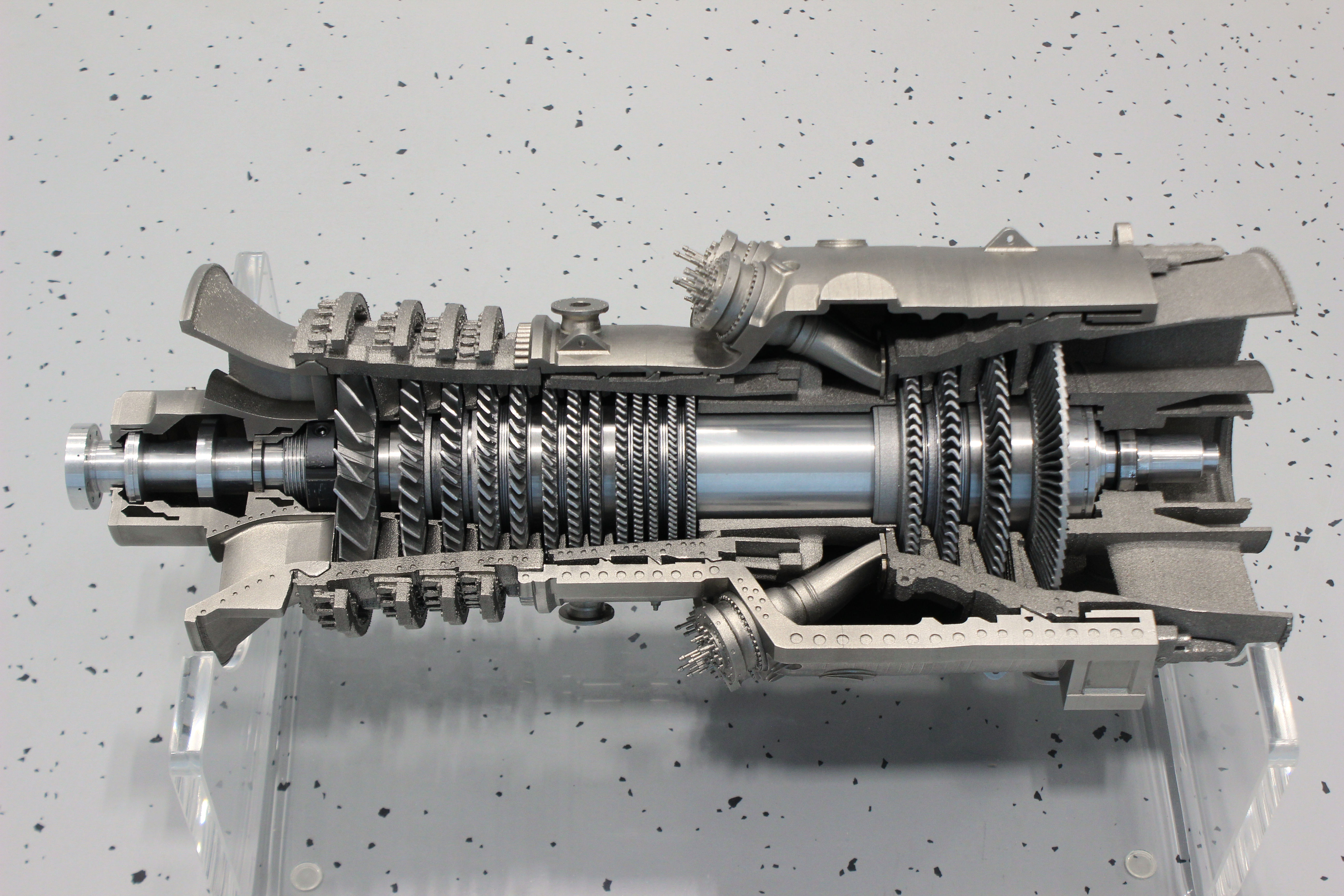

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) has developed a prototype gas turbine for power generation using powder bed-based additive manufacturing (AM).

According to the institute, all aspects of the 1:25 scaled model, besides the shaft, were manufactured using laser beam melting (LBM) and selective electron beam melting (SEBM), with additional machining. It comprises 68 parts made of aluminum, 316L steel and Ti-6Al-4V titanium, in comparison with the 3000 individual parts that make up the original component, IFAM says.

Production planning was reportedly important to consider the accuracy and roughness of the surfaces, support structures required, and component size. In one example, the shaft and turbine stages had to be able to rotate freely between the stator stages, while the individual components of the demonstrator had to be connected to each other by screwing and plugging in.

IFAM says that while the combination of different materials commercially available from respective plant manufacturers is demonstrated in the component, not all processed materials correspond to the target materials for turbines. Currently, these materials cannot yet be processed in such a way that they can be offered commercially, the institute said.

This story uses material from Fraunhofer, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.