Tool manufacturer Ceratizit has developed FreeTurn tooling as part of its high dynamic turning (HDT) system.

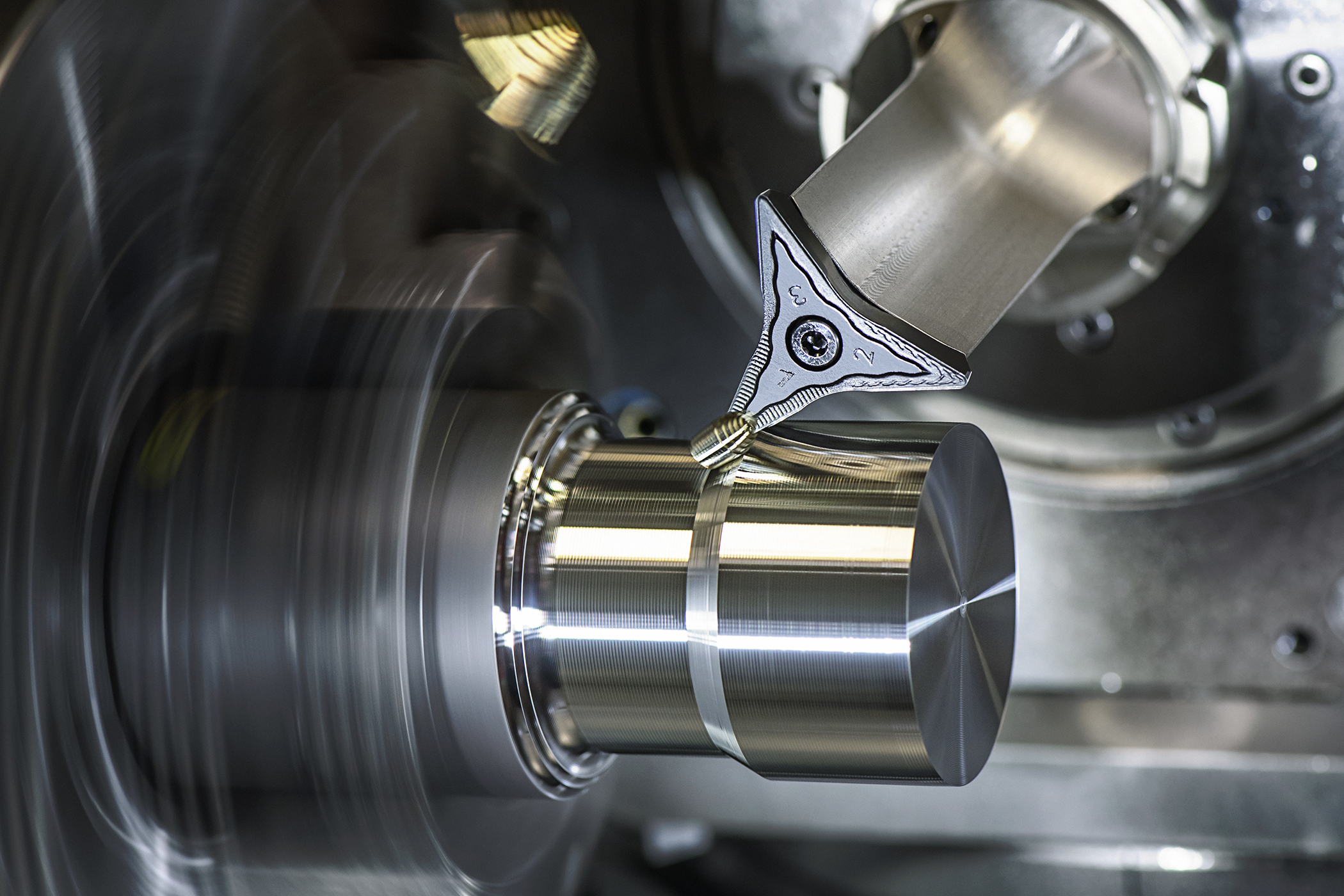

Using FreeTurn tooling, the tool holder, its slim shank and the axial concept which improves the direction of the cutting forces into the spindle, form a stable unit. At the cutting end, there is a multi-sided insert, which is screwed in place. According to the company, the FreeTurn insert can consist of several cutting edges with different properties, allowing for different angle points, corner radii or chip breakers, while different coatings and cutting materials are conceivable. The tool can therefore be adapted to the machining requirements.

According to the company, using high dynamic turning (HDT) combined with the company’s FreeTurn tooling, means that it is now possible to carry out all traditional turning operations such as roughing, finishing, contour turning, face turning and longitudinal turning with just one tool.

With HDT, the tool approach and point of contact in the machine can be varied as opposed to conventional turning with a fixed tool, and instead of the static position of the insert in the holder, the milling spindle can now be used to produce the corresponding approach angle to the workpiece, Ceratizit says. The use of the spindle drive, in conjunction with the slim, axial tool design of the FreeTurn tools creates a degree of freedom of 360° without the risk of collision, improving flexibility.

Due to the rotation around its own tool axis, the cutting edge change can be done without interrupting the cutting process, and the angle of approach is freely variable at any time and can even be changed while cutting, according to the company. Depending on the machine capabilities, the technology can be used functionally in all areas of turning operations.

Ceratizit says that four indexable insert geometries have now been launched, including indexable inserts for machining steel/stainless steel (2x roughing and 1x finishing, 3x roughing, symmetrical) and for aluminum (3 cutting edges, symmetrical). The holders are available with a range of different overhang lengths for each size and are available for the HSK-T and PSC machine interfaces.

This story uses material from Ceratizit, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.