Olympus has launched a new microscope for the observation and inspection of metal components.

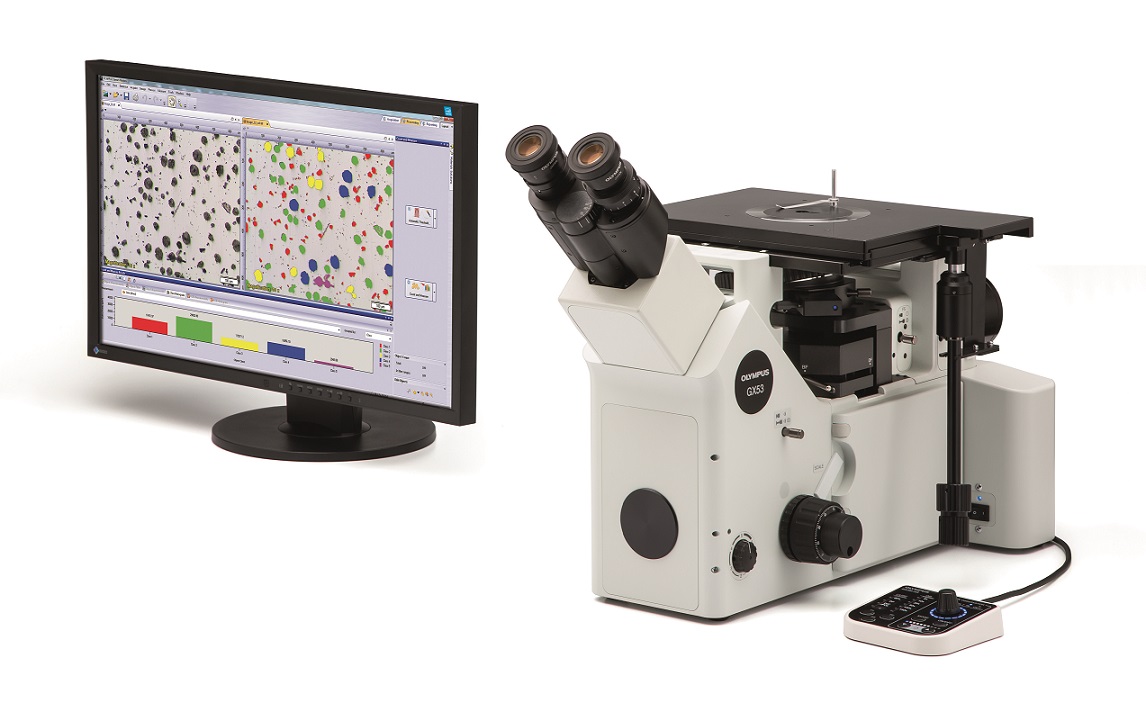

The Olympus GX53 inverted metallurgical microscope features an LED light source for long life and low power consumption. It also incorporates the latest version of OLYMPUS Stream image analysis software for improved observation and reporting capabilities, the company said.

Inverted metallurgical microscopes observe samples from underneath, enabling the user to inspect thick or heavy samples without adjusting the orientation of the sample surface. This ability reportedly makes the GX53 microscope a practical tool for viewing the microstructure of metals used in automotive and other manufactured metal components.

The microscope also includes for the first time MIX observation technology making it possible to obtain surface structure images with improved clarity. MIX technology can combine darkfield with another observation method, such as brightfield, fluorescence or polarization. It can enable users to view samples that are difficult to see with conventional microscopes. The circular LED illuminator used for darkfield observation has a directional function where one or more quadrants are illuminated at a given time. This reduces a sample’s halation and is useful for visualizing its surface texture.

This story is reprinted from material from Olympus, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.