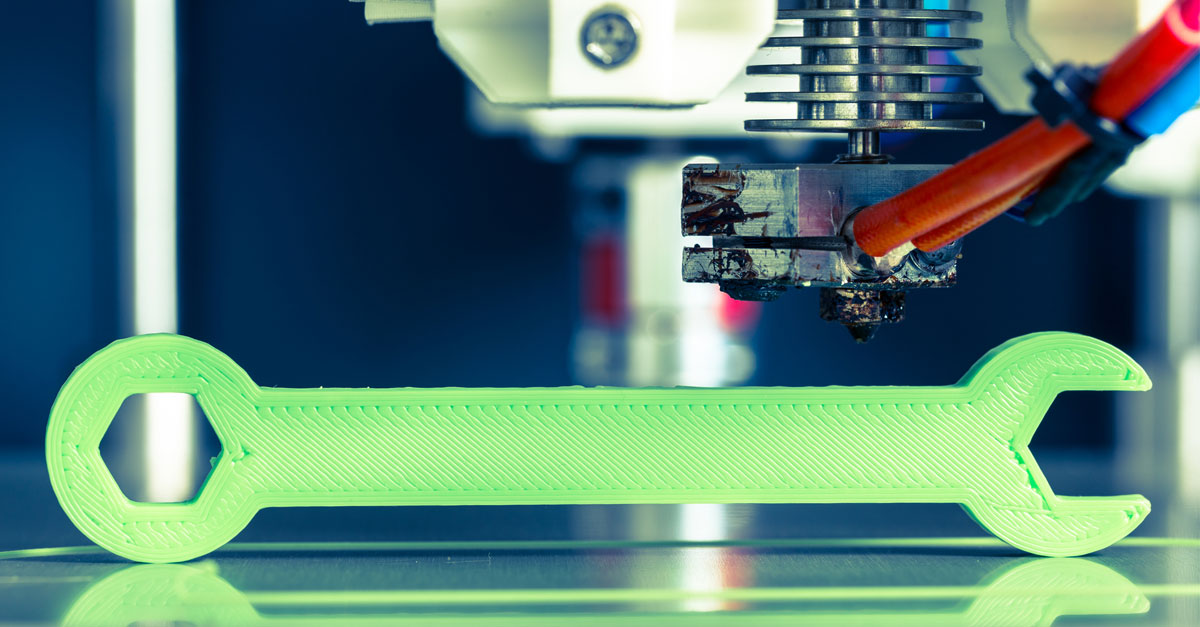

Research institutes the Fraunhofer Institute for Microstructure of Materials and Systems and Brightlands Materials Center plan to jointly improve fiber-reinforced thermoplastics to make them more suitable for 3D printing on an industrial scale. 3D print polymeric materials can lead to lightweight products, a more flexible design and the opportunity to integrate sensors. Fraunhofer IMWS and Brightlands Materials Center want to combine the advantages of individual production by means of 3D printing and the properties of fiber-reinforced thermoplastic materials. The partners aim to develop a better understanding of the manufacturing process in 3D printing, for example, the question of how the reinforcing fibers are embedded in the matrix and how this affects the properties of the printed composite part, such as stiffness or tensile strength. In the next step, the partners intend to develop materials and technologies to make more resilient and tailor-made components such as spare parts for automotive, aerospace and construction industries. ‘The success story of 3D printing so far shows the great potential of this technology. However, many parameters can still be significantly improved, such as the speed of production and the mechanical stability of components,’ said Dr Ralf Schlimper from the Fraunhofer Institute.

This story is reprinted from material from Fraunhofer, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.