3D Systems has worked with machining company Wilting, based in the Netherlands, to 3D print components designed for higher performance in semiconductor capital equipment.

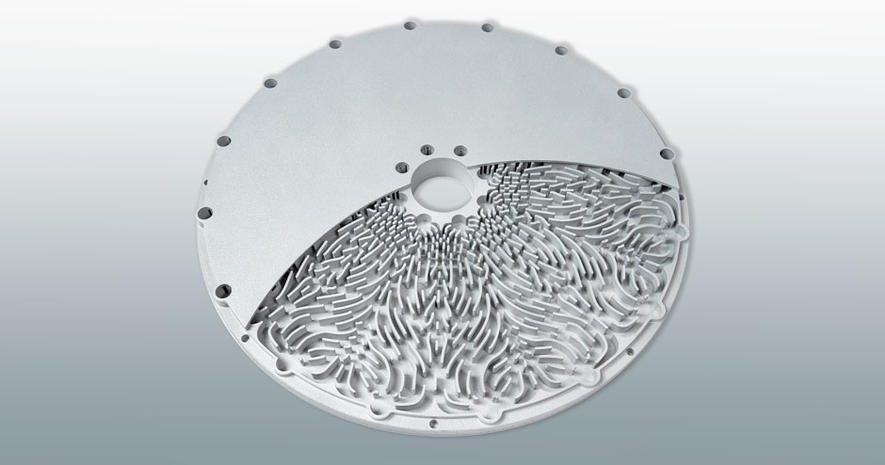

According to the company, as microchip package sizes continue to decrease, semiconductor manufacturers are under pressure to improve lithography capabilities. When used to make to semiconductor lithography and wafer processing equipment such as manifolds, wafer tables, wafer handling systems, flexures, and brackets, additive manufacturing (AM) can help improve the performance and reliability of the part.

Some specific improvements include reducing liquid induced disturbance forces by as much as 90%, decreasing weight and volume by as much as 50%, and increasing reliability, 3D Systems says. For example, compared to a traditionally manufactured manifold assembly with 20+ parts, AM can deliver a single monolithic part for increased reliability, and improved manufacturing and yield.

This story uses material from 3D Systems, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.