Technology company Trumpf has developed a new green laser with pulse function, enabling pure copper and precious metals to be processed in a 3D printer for reportedly the first time. It works by connecting the company’s TruDisk 1020 disk laser with the TruPrint 1000 3D printer.

‘Conventional systems use an infrared laser as the beam source, but its wavelength is too long and it can't weld highly reflective materials such as copper and gold,’ said Thomas Fehn, Trumpf additive manufacturing sales manager. ‘This can be done with laser light in the green wavelength spectrum.’ According to Fehn, this could open up new possibilities for 3D printing, for example in the electronics and automotive industries.

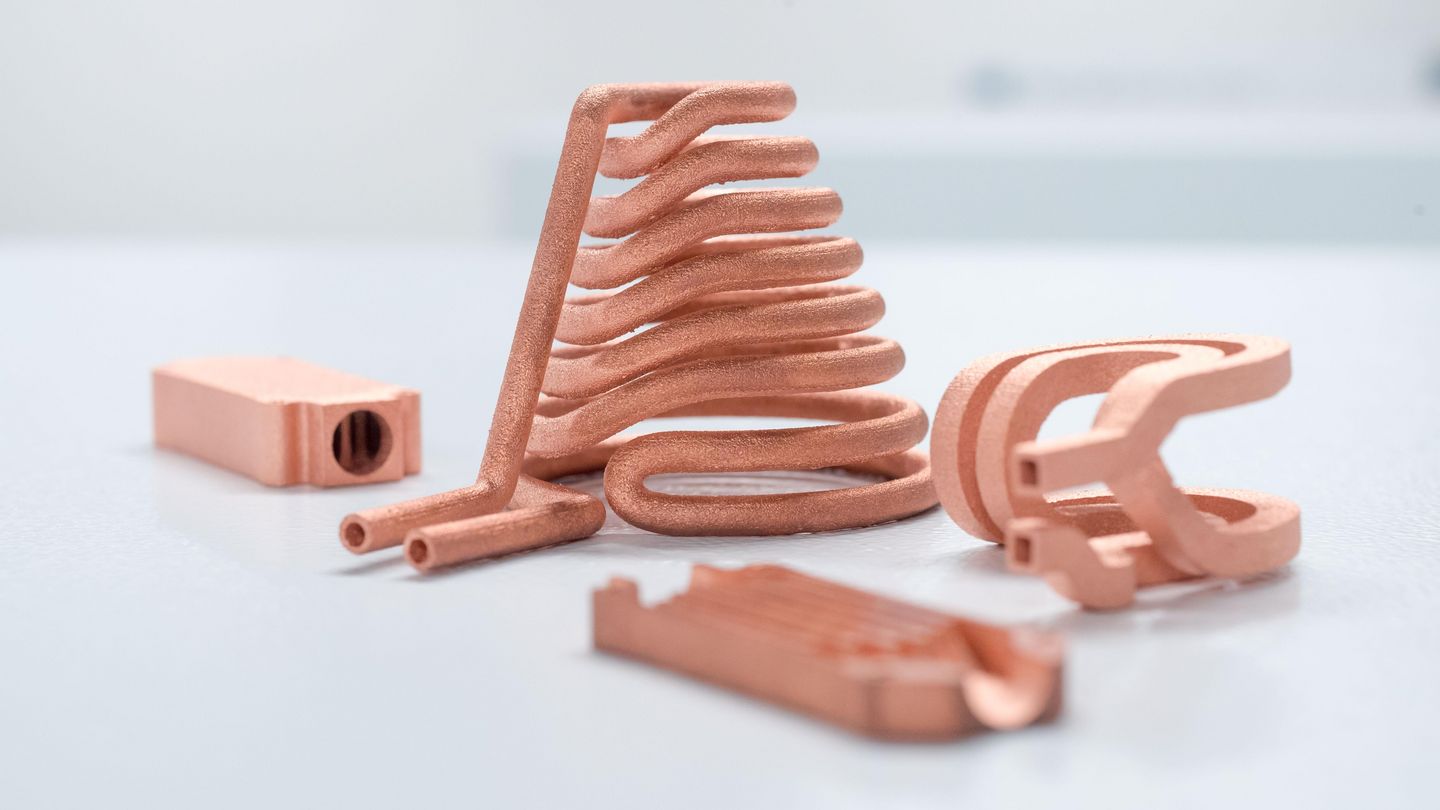

‘Pure copper can be used to print particularly conductive inductors and heat exchangers,’ said additive manufacturing technology director Tobias Baur. The green laser also holds great potential for gold printing in the jewelry industry, enabling individual pieces to be produced on demand, with less waste, the company said.

This story is reprinted from material from Trumpfwith editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.