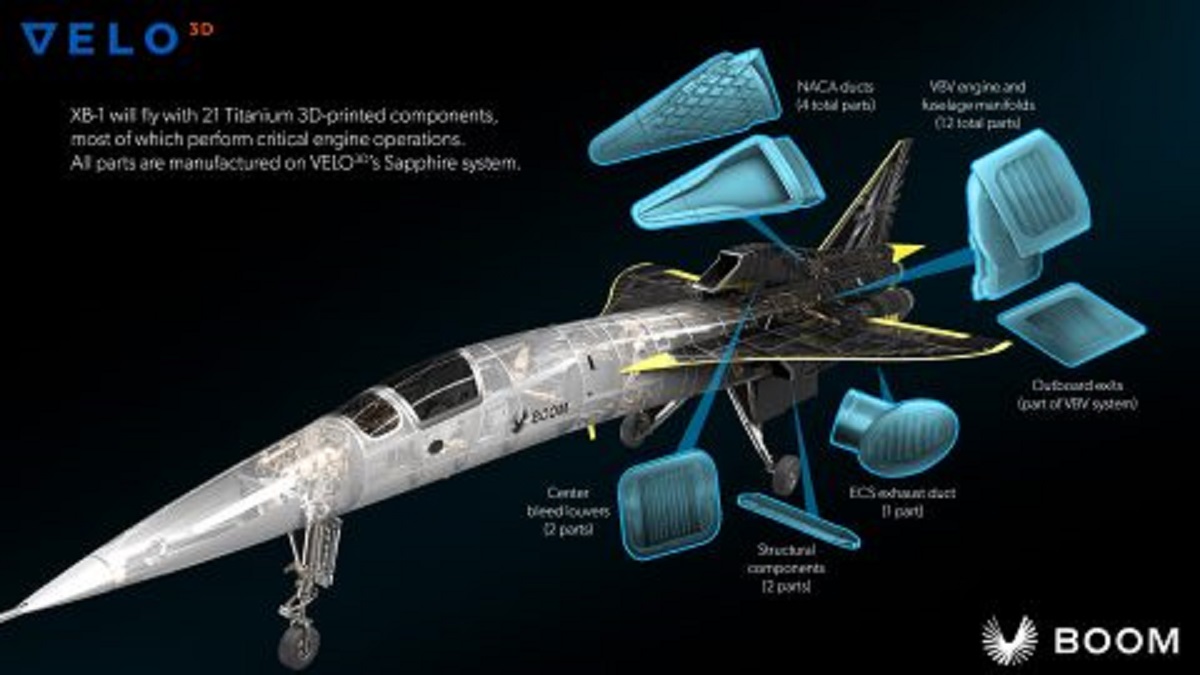

VELO3D has supplied 21 3D printed components for Boom Supersonic’s XB-1 aircraft, the world’s first independently developed supersonic jet.

This follows Boom Supersonic and VELO3D’s formation of a partnership in 2019 to make flight hardware for the XB-1, and running of a series of qualification trials on VELO3D’s Sapphire system. The printed titanium parts are used for engine hardware, the environmental control system, and structural components, and have tall, thin walls with high aspect ratios, which are inherently difficult to manufacture with either traditional processes such as welding and casting, or even most existing 3D printing technologies.

‘Aviation hardware is especially difficult to manufacture with 3D metal printing, due to challenging aerodynamic designs that must be balanced with superior durability and high temperature requirements,’ said Benny Buller, CEO and founder of VELO3D. ‘VELO3D’s technology allows the production of lightweight, complex designs for mission-critical applications in the toughest operating conditions.’

This story uses material from VELO3D, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.