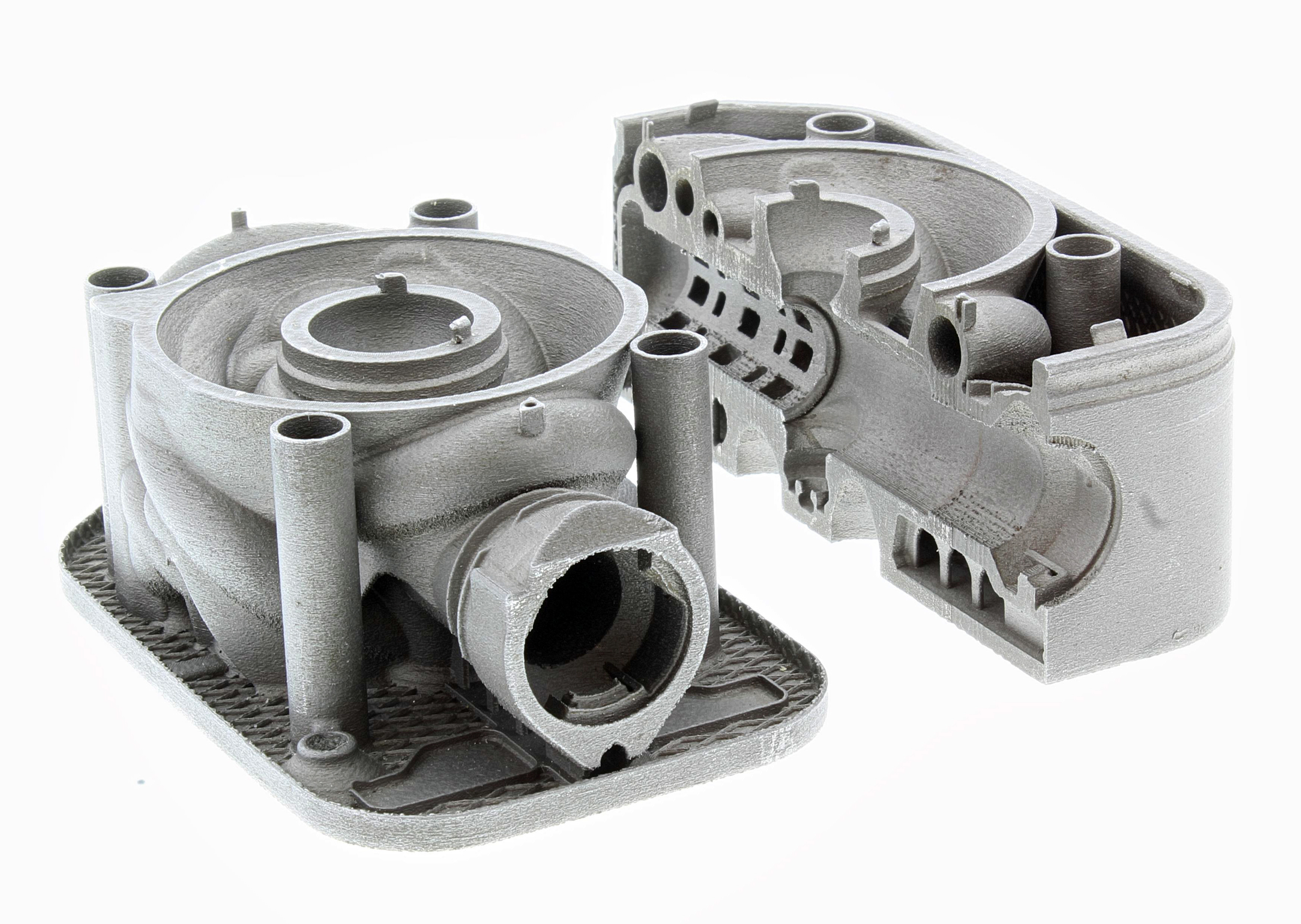

Renishaw has worked together with Domin Fluid Power to improve its productivity when manufacturing direct drive valves using metal additive manufacturing (AM).

According to Renishaw, the company can now manufacture smaller, more efficient drives and reduce cycle times from five and a half hours to just one.

'Metal AM allows you to stretch the art of what is possible in the fluid power sector,' said Marcus Pont, general manager of Domin Fluid Power. 'After spending years on testing different prototypes and designs we have developed our knowledge in AM that will enable us to produce efficient parts for customers. For example, we have designed one of our drives that is 25% of the original size, 25% more powerful and produced at a third of the cost.'

This story uses material from Renishaw, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.