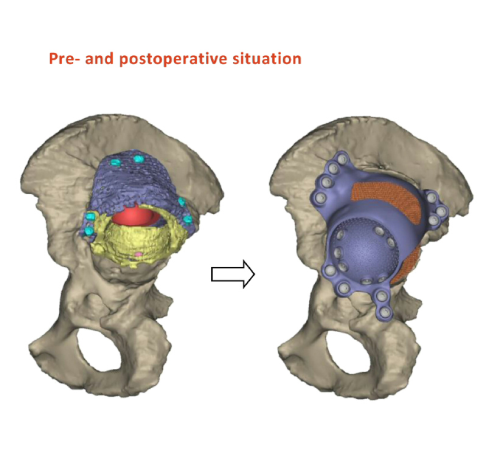

The 3D printed hip, made from titanium, was designed using the patient’s CT scan and CAD CAM technology to the patient’s exact specifications and measurements.

The implant will provide a new socket for the ball of the femur bone to enter. Behind the implant and between the pelvis, doctors have inserted a graft containing bone stem cells. The graft acts as a filler for the loss of bone. The patient’s own bone marrow cells have been added to the graft to provide a source of bone stem cells to encourage bone regeneration behind and around the implant.

“The benefits to the patient through this pioneering procedure are numerous,” said Douglas Dunlop, consultant orthopaedic surgeon at Southampton General Hospital, who conducted the operation. “The titanium used to make the hip is more durable and has been printed to match the patient’s exact measurements – this should improve fit and could reduce the risk of having to have another surgery.

Orthopaedic development

“The bone graft material that has been used has excellent biocompatibility and strength and will fill the defect behind the bone well, fusing it all together.”

Over the past decade Dunlop and Professor Richard Oreffo, at the university, have developed a translational research programme to drive bone formation using patient skeletal stem cells in orthopaedics.

“The 3D printing of the implant in titanium from CT scans of the patient and stem cell graft is cutting edge and offers the possibility of improved outcomes for patients,” said Professor Oreffo. “Fractures and bone loss due to trauma or disease are a significant clinical and socioeconomic problem. Growing bone at the point of injury alongside a hip implant that has been designed to the exact fit of the patient is exciting and offers real opportunities for improved recovery and quality of life.”