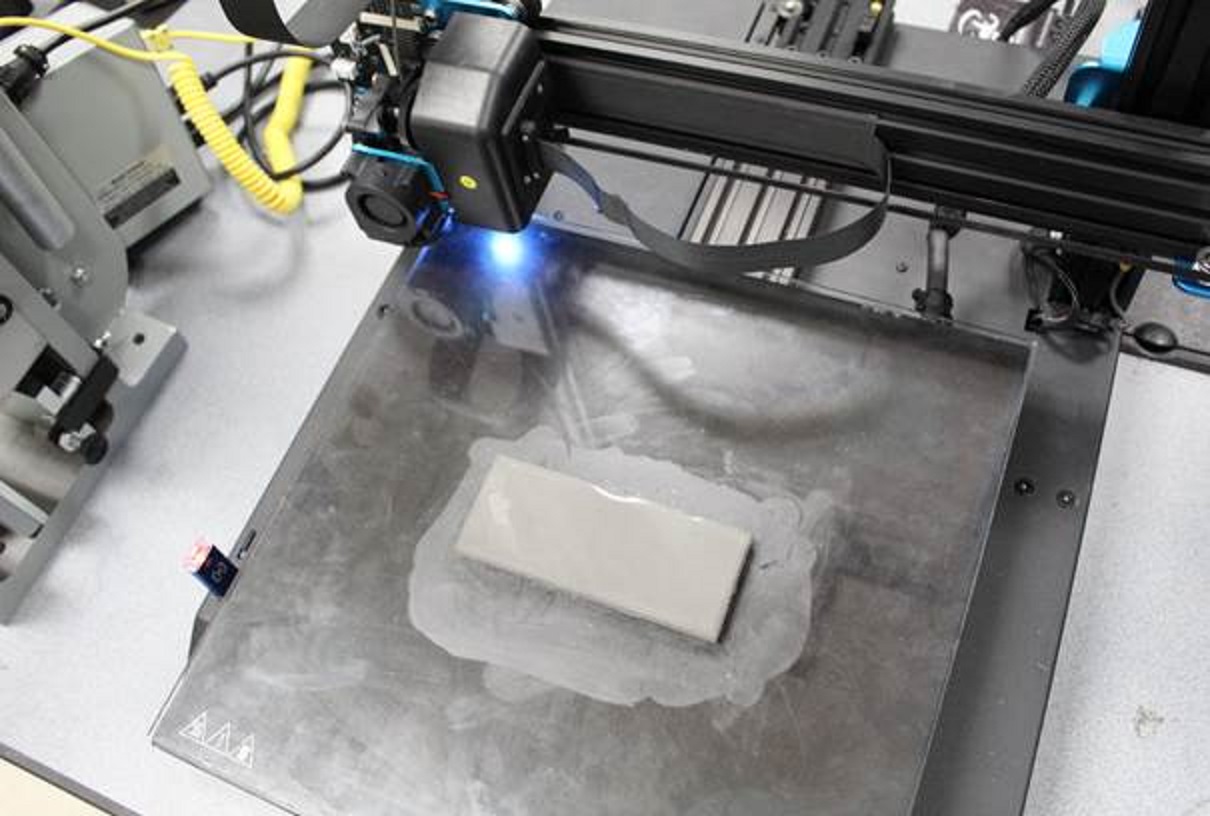

Somerset Community College’s (SCC) additive manufacturing program has successfully 3D printed numerous 316L stainless steel metal parts on a range of low cost desktop 3D printers.

Several of these parts were then successfully tungsten inert gas (TIG) welded together. According to SCC, this project is one of the first applications where fully metal parts 3D printed on a US$600 desktop printer have been successfully welded together using conventional welding techniques.

The 3D printing process is based on bound metal additive manufacturing (BMAM), which said the college says could be one of the fastest growing methods of additive production over the next several years.

‘The welds flowed very smoothly and we had very good penetration control,’ said SCC senior welding professor, Karl Watson. ‘Because of the nature of 3D printing and research we have seen around the concept of welding such parts, I expected to see more porosity in the weld, but that wasn’t the case with these specimens at all.’

Preliminary testing of the parts has also shown hardness values slightly less than stock 316L, but microscopic inspection after finishing has not shown any inconsistencies thus far, SCC said. Watson also noted that the heat dissipation during the welding process of the 3D printed stainless was higher than conventional stock stainless.

This story uses material from SCC, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.