How can the cutting of 'gummy' metals be improved? Researchers at Purdue University have now come up with an answer – and their findings may help in manufacturing products and reducing component failures.

In a previous study, the researchers showed that applying a permanent marker or Sharpie, glue or adhesive film made it easier to cut metals such as aluminum, stainless steels, nickel, copper and tantalum for industrial applications (see Marking where to cut ‘gummy’ metals). Marking the metal surface to be machined with a film of ink or adhesive dramatically reduced the force of cutting, leaving a clean cut in seconds. Now, the researchers have discovered how these films produce their effect.

"We have found that you only need the organic film from the markers or glue to be one molecule thick for it to work," said Srinivasan Chandrasekar, professor of industrial engineering at Purdue. "This ultra-thin film helps achieve smoother, cleaner and faster cuts than current machining processes. It also reduces the cutting forces and energy, and improves the outcomes for manufacturing across industries such as biomedical, energy, defense and aerospace."

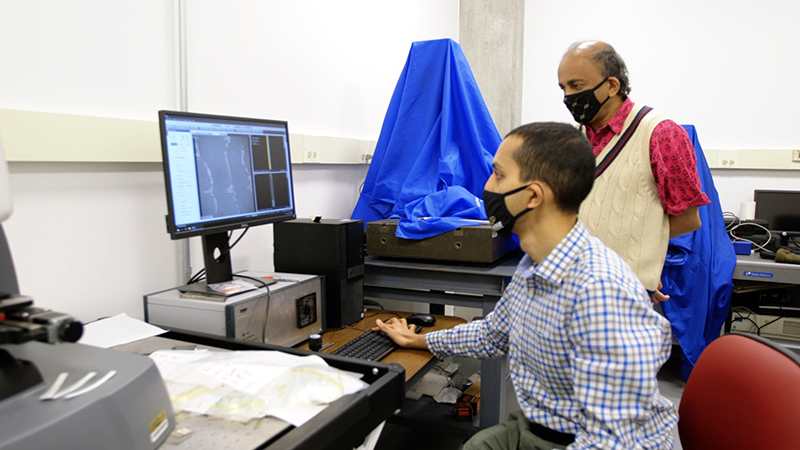

The researchers report their findings in a paper in Science Advances. The study involves a collaboration between researchers at Purdue, Osaka University in Japan and the Indian Institute of Science, and is supported by the US National Science Foundation and the US Department of Energy.

If a significant improvement can be made to the machinability of gummy metals or alloys – that is, how well they cut, drill or grind – then there is potential for lowering the cost of products, improving their performance and enabling new and improved product designs.

Using organic monolayer films created by molecular self-assembly, the researchers found that the molecule chain length and its adsorption to the metal surface are key to realizing these improvements. By using the 'right' organic molecules, the metal is locally embrittled, resulting in improved machining.

"We are also learning through our discovery more about how environmental factors influence failure of metals," said Anirudh Udupa, a researcher in Purdue's School of Industrial Engineering and a lead author of the paper. "As we decipher how the organic molecular films improve the machinability of these metals, the better also is our understanding of common environment-assisted failures in metals, such as stress-corrosion cracking, hydrogen embrittlement and liquid metal embrittlement."

This story is adapted from material from Purdue University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.