Sumitomo will also show a new range of shell milling cutter bodies with a choice of insert pitches suitable for lower power machines, and new turning inserts which give an improved performance when light finishing super alloy and hardened steel.

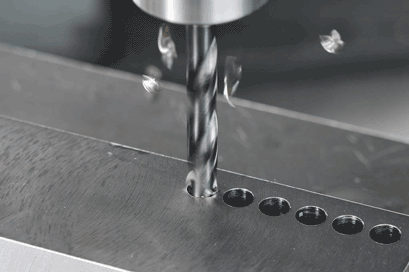

The extended range of SumiDrill SDP Power-Series drills has the advantage of a ‘double margin’ relief within the periphery of the drill body which reduces the contact area while still supporting the tool in the material being drilled. It has new flute geometry which creates an elliptical form enabling increased chip evacuation from the cutting zone for hole sizes between 3 mm and 20 mm that ensures holes with depth-to-diameter ratios up to 7xD can be efficiently drilled.

Sumitomo’s PCX 70 AlCrTin solid carbide SDP tool has a hard and toughened multi-layer coating which improves wear resistance by providing low levels of chip to surface adhesion. This coating can restricts built-up-edge on the drill enabling greater penetration rates to be maintained. This means SDP drills can be applied to a wide range of materials including hardened steel up to 45 HRC, cast iron, aluminium and always difficult to drill copper.

Improved surface quality

To improve applications where the use of lower power machine tools or where cutting forces can restrict performance on steel and cast iron components, the Sumitomo WGX Wavemill Series of 45 deg shell milling cutter bodies provide a choice of three different insert pitches between three and 10 teeth, four and 14 teeth and five and 24 teeth. By using Sumitomo’s wiper-edge insert which has a large rake angle with the WGX bodies, surface quality can be improved and a chamfer on the insert reduces the likelihood of insert edge chipping and the generation of burrs.