Stratasys Ltd and Siemens have made a formal partnership to help incorporate additive manufacturing (AM) into the traditional manufacturing workflow.

The company want to help AM become a universally recognized production practice which can benefit multiple industries, including aerospace, automotive, transportation, energy and industrial tooling.

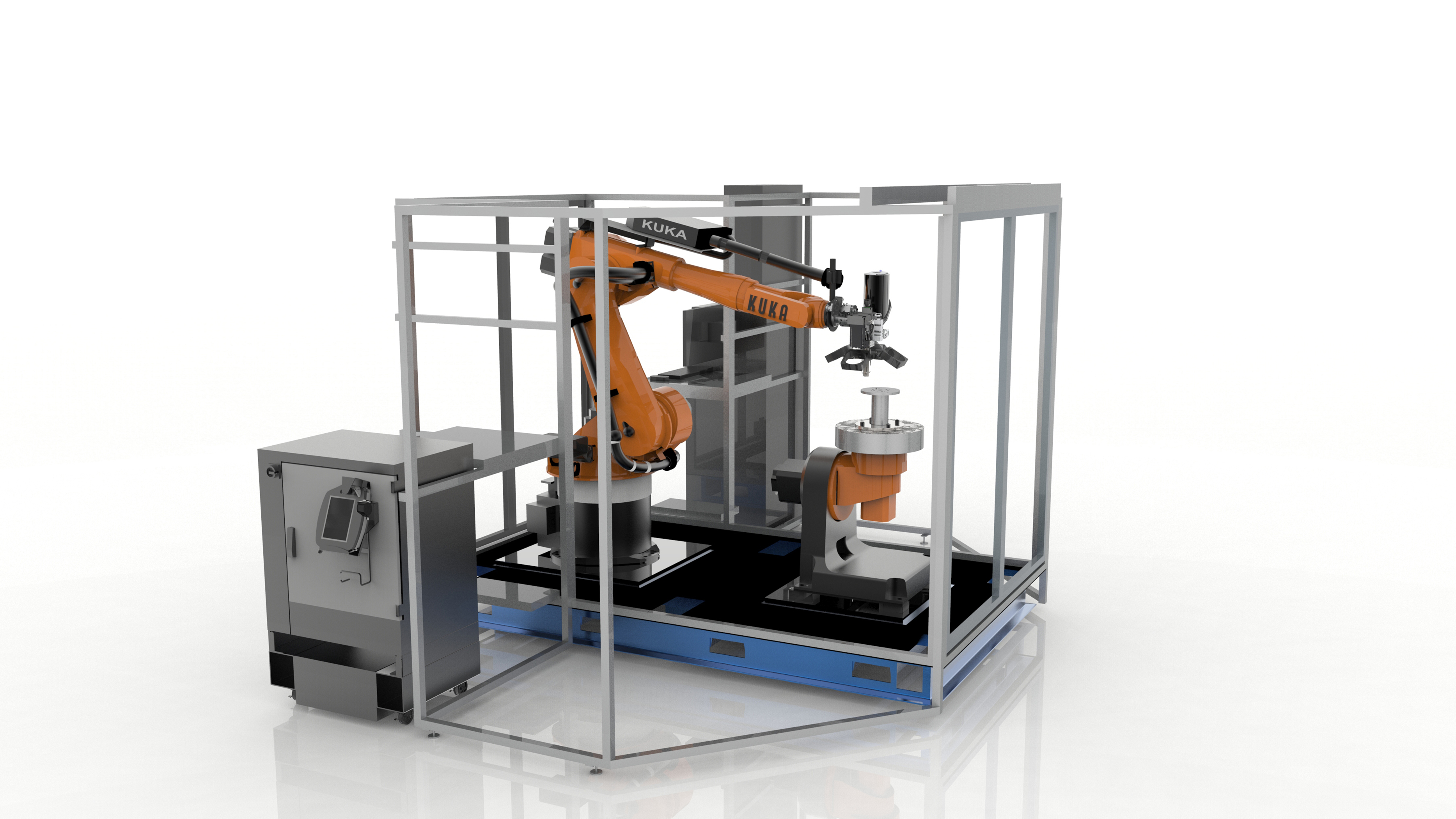

Stratasys and Siemens have been collaborating on multiple projects including the direct link from Siemens’ NX software for CAD/CAM/CAE to Stratasys’ GrabCAD Print platform – enabling a design-to-3D print workflow – and the recently previewed Stratasys Robotic Composite 3D Demonstrator that incorporates Siemens’ product lifecycle management (PLM) software and its motion control and CNC automation technologies.

‘Siemens is enthusiastic about this partnership with Stratasys and the opportunity to help our customers adopt a new manufacturing mindset that we believe will result in better products produced more economically and delivered more efficiently,’ said Zvi Feuer, SVP manufacturing engineering software, Siemens PLM Software. ‘We are committed to the industrialization of additive manufacturing with all of its unique advantages, including complex part geometries, on-demand production and mass customization.’

‘While additive manufacturing technology has made great strides over the past years, additional criteria are required for it to take its place in volume production environments and become as commonplace as CNC,’ the company said in a press release. ‘Ideally, additive manufacturing solutions should deliver robust, repeatable and reliable operational performance with predictable properties across a broad portfolio of materials that are certifiable for specific applications and that are driven by a seamless, digital integration from design to production.’

This story is reprinted from material from Siemens, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.