Silicon carbide-infused magnesium is super strong

Researchers from UCLA in the US have developed a new metal, composed of magnesium infused with ceramic silicon carbide nanoparticles, that could be used to make lighter airplanes, spacecraft and cars.

The super-strong, light structural metal reportedly has high specific strength and modulus, or stiffness-to-weight ratio.

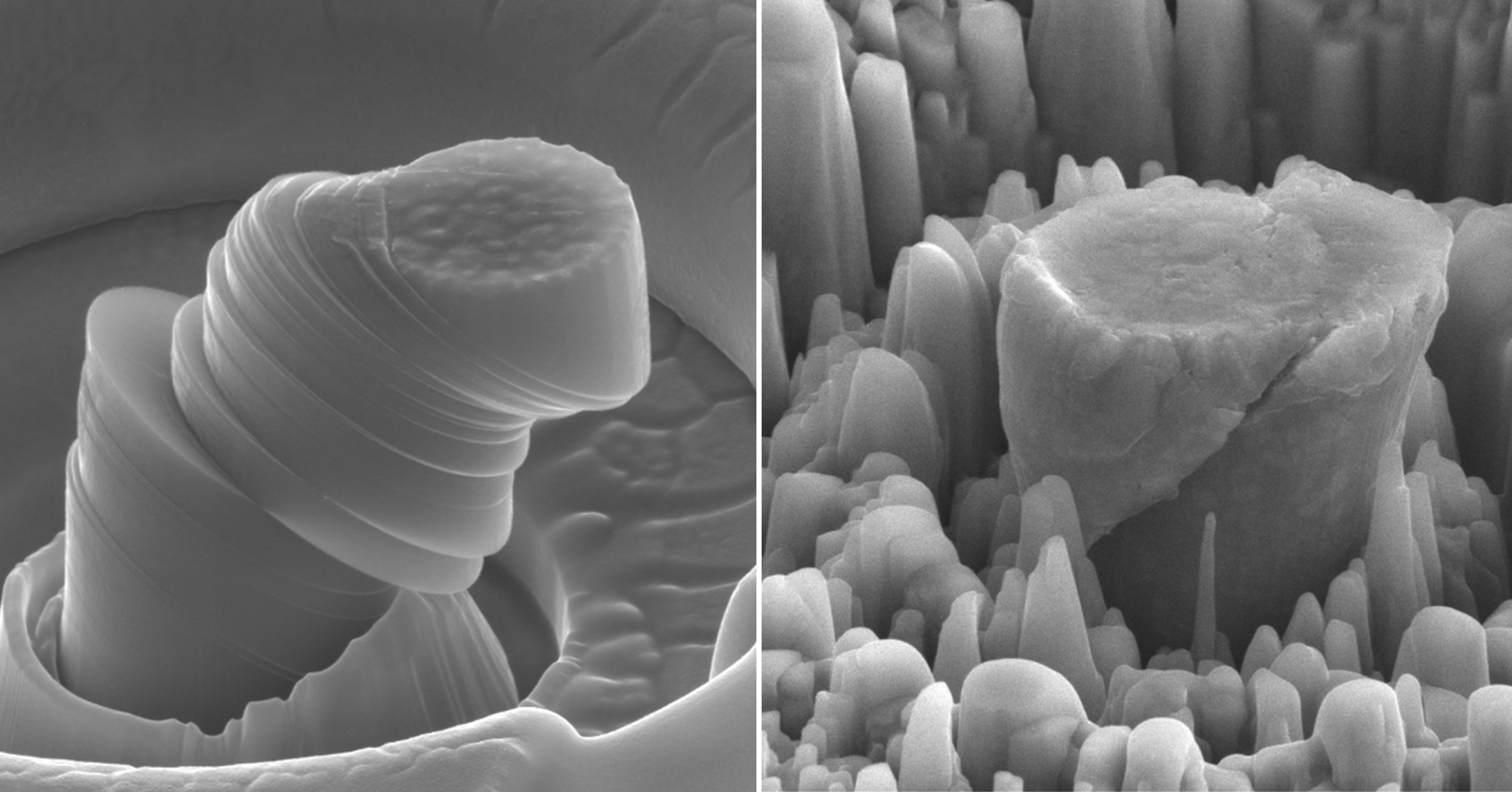

To create the metal, the team found a new way to disperse and stabilize a large number of silicon carbide particles smaller than 100 nanometers in molten metals. They also developed a scalable manufacturing method that could pave the way for more high-performance lightweight metals. The researchers’ technique added significant strength, stiffness, plasticity and durability under high temperatures. The material also showed superior stability at high temperatures.

‘It’s been proposed that nanoparticles could really enhance the strength of metals without damaging their plasticity, especially light metals like magnesium, but no groups have been able to disperse ceramic nanoparticles in molten metals until now,’ said Xiaochun Li, the principal investigator on the research and Raytheon chair in manufacturing engineering at UCLA. ‘With an infusion of physics and materials processing, our method paves a new way to enhance the performance of many different kinds of metals by evenly infusing dense nanoparticles to enhance the performance of metals to meet energy and sustainability challenges in today’s society.’

Nanoparticle dispersion

Ceramic particles have long been considered as a potential way to make metals stronger. However, with microscale ceramic particles, the infusion process results in a loss of plasticity. Nanoscale particles, by contrast, can improve strength while maintaining or even improving metals’ plasticity. However, nanoscale ceramic particles tend to clump together rather than dispersing evenly, due to the tendency of small particles to attract one other. To counteract this issue, researchers dispersed the particles into a molten magnesium zinc alloy. The newly discovered nanoparticle dispersion relies on the kinetic energy in the particles’ movement. This stabilizes the particles’ dispersion and prevents clumping.

To further improve the new metal’s strength, the researchers used a technique called high-pressure torsion to compress it.

The new metal (more accurately called a metal nanocomposite) is about 14% silicon carbide nanoparticles and 86% magnesium.

The research was published in Nature.

This story uses material from UCLA, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.