By Liz Nickels

Boron carbide, like tungsten carbide, is used in many kinds of machinery to make tools and other kinds of hard wearing equipment. Abrasive jets, which are used to cut hard or heat sensitive material, need to be manufactured from hard materials to minimise wear. In addition, boron carbide is very effective at absorbing neutrons, which means it has potential for use in the nuclear industry to protect against radiation.

Currently, boron carbide is produced in the form of large ingots, produced by mixing petroleum coke with boron oxide at temperatures of up to 2000°C. These ingots then have to be ground into fine grains before being manufactured into the required shape. This method uses a lot of energy and time, making boron carbide products up to 10 times more expensive than other, less hard wearing ceramic materials which currently dominate the market.

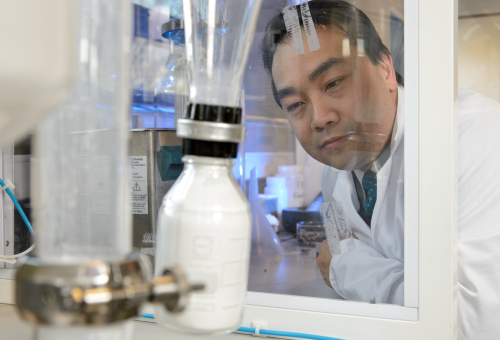

A team led by Isaac Chang has devised a method which substitutes a carbohydrate-based compound for the petroleum coke. The boron oxide and carbohydrate are mixed in water to form a solution which mixes the carbon and boron sources at a molecular level. The solution is then atomised into fine droplets which convert into a powder on cooling. When this powder is heated at a temperature below 1500 °C fine boron carbide particles are produced, ready for processing.

Reducing cost

“The raw materials we are using are very cheap,” said Dr Chang. “They are also highly active ingredients, which means we can use much lower temperatures to produce the chemical reaction that we need, making the process less energy intensive. Also, because our end product is a powder, rather than an ingot, there is no need for grinding, which removes a costly and inefficient step from the process.”

Because boron carbide is one of the lightest materials on the market, relative to its strength, it is also very important in the development of new ceramic armours for the protection of dismounted soldiers as well as military vehicles and aircrafts against ballistic threats.

The team have just completed a series of tests to demonstrate how this process can be scaled up to produce larger yields and are now working further refine the process. They are seeking licensing partners to commercialise the technology. The project was funded by the UK’s Defence Science and Technology Laboratory.