An international team of researchers from the University of Minnesota Twin Cities and Kiel University in Germany have discovered a path that could lead to shape-shifting ceramic materials, potentially improving everything from medical devices to electronics. The researchers report their work in a paper in Nature.

Anyone who has ever dropped a coffee cup and watched it break into several pieces, knows that ceramics are brittle. Subject to the slightest deformation, they shatter. But ceramics are used for more than just dishes and bathroom tiles, they are also found in electronics, because, depending on their composition, they can be semiconducting, superconducting, ferroelectric or insulating. Ceramics are also non-corrosive and used for making a wide variety of products, including spark plugs, fiber optics, medical devices, space shuttle tiles, chemical sensors and skis.

At the other end of the materials spectrum are shape-memory alloys, which are some of the most deformable or reshapable materials known. Shape-memory alloys rely on this tremendous deformability when functioning as medical stents, the backbone of a vibrant medical device industry both in the Twin Cities area and in Germany.

The origin of this shape-shifting behavior is a solid-to-solid phase transformation. Different to the process that involves crystallization, melting and recrystallization, crystalline solid–solid transitions take place solely in the solid state. By changing temperature (or pressure), a crystalline solid can be transformed into another crystalline solid without entering a liquid phase.

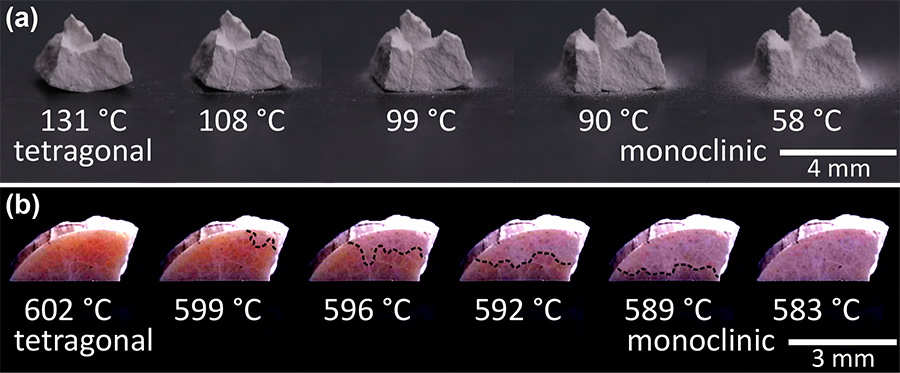

In this new research, the route to producing a reversible shape-memory ceramic was anything but straightforward. The researchers first turned to an approach that has worked well for the discovery of new metallic shape-memory materials, which involves a delicate tuning of the distances between atoms by compositional changes, so that two distinct phases fit together well. But when they tried this approach with ceramics, instead of improving the deformability, they observed that some specimens exploded when passing through the phase transformation. Others gradually fell apart into a pile of powder, a phenomenon they termed 'weeping'.

Eventually, however, they were able to find a composition that displayed a reversible transformation, with the ceramic material easily transforming back and forth between the phases, much like a shape-memory material. The mathematical conditions under which reversible transformation occurs can be applied widely and provide a way toward the paradoxical shape-memory ceramic.

“We were quite amazed by our results. Shape-memory ceramics would be a completely new kind of functional material,” said Richard James, a professor in the University of Minnesota’s Department of Aerospace Engineering Mechanics and a co-author of the paper. “There is a great need for shape-memory actuators that can function in high temperature or in corrosive environments. But what excites us most is the prospect of new ferroelectric ceramics. In these materials, the phase transformation can be used to generate electricity from small temperature differences.”

The team from Germany was responsible for the experimental part, and the chemical and structural investigation at the nanoscale. “For the explanation of our experimental discovery that, contrary to expectation, the ceramics are extremely incompatible and explode or decay, the collaboration with Richard James’ group at the University of Minnesota was very valuable,” said Eckhard Quandt, a professor in the Institute for Materials Science at Kiel University and a co-author of the paper. “The theory developed on this basis not only describes the behavior, but also shows the way to get to the desired compatible shape-memory ceramics.”

James also highlighted the importance of the collaboration between the University of Minnesota and Kiel University. “Our collaboration with Eckhard Quandt’s group at Kiel University has been tremendously productive,” he said. “As in all such collaborations, there is sufficient overlap that we communicate well, but each group brings plenty of ideas and techniques that expand our collective ability to discover.”

This story is adapted from material from the University of Minnesota, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.