Understanding the complex physics behind additive manufacturing (AM) is a vital step in developing the technology, according to a new paper authored by Lawrence Livermore National Laboratory (LLNL) researchers.

Even though AM has quickly progressed into a production technology, 3D printing of metal parts for industries such as aerospace and health care is hampered by a lack of confidence in the finished parts, said Wayne King, leader of the lab’s Accelerated Certification of Additively Manufactured Metals Project (ACAMM). However, this hurdle could be overcome by a combination of physics-based modeling and high-performance computing to determine the optimal parameters for building each part.

‘If we want to put parts into critical applications, they have to meet quality criteria,’ said King. ‘Our project is focused on developing a science-based understanding of the additive manufacturing process to build confidence in the quality of parts. We want to accelerate certification and qualification to take advantage of the flexibility that metal additive manufacturing gives us. Ideally, our plants would like to build a part on Monday that can be qualified and on the same machine on Tuesday build a different part that can also be qualified.’

Developing parameters

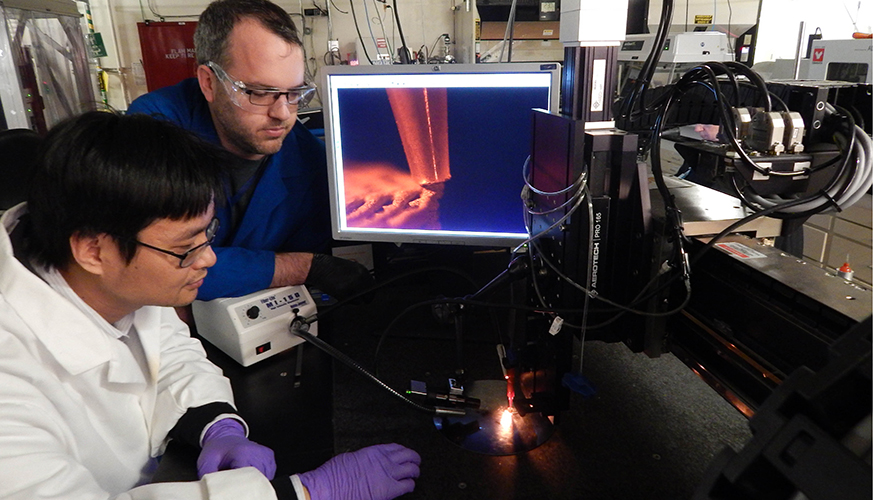

In the paper published in the Applied Physics Reviews, King and his team describe two physics-based models for the selective laser melting process on scales varying from the particulate powder to the whole part or component.

The team’s powder model addresses the formation, evolution and solidification of the melt pool, and could be used to better understand how laser power, speed, beam size and shape affect different types of metals and develop parameters for new materials, the researchers said. It also could provide insights into the dominant physical processes in the laser-powder interaction and guide improvements to the SLM method in the future.

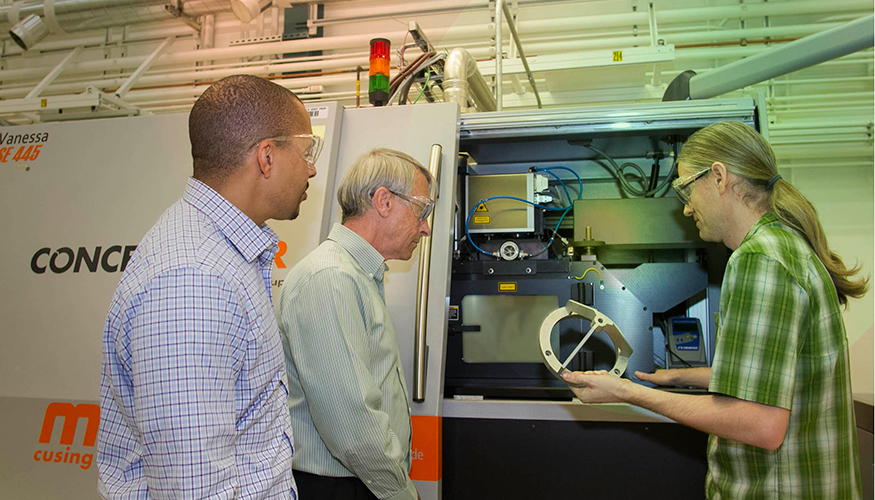

The part-scale model simulates the 3D printing of full-scale parts, calculating the effects of stress and heat arising from a given type of metal and laser process parameters. It could improve predictions of deformation and stresses during printing that can lead to part failure, as well as help improve quality, eliminating much of the guesswork involved in creating new parts.

‘By modeling the fabrication you can see what is the aggregate behavior of the part and essentially build in compensations,’ said Bob Ferencz, LLNL’s division leader for Computational Engineering, and co-author on the paper. ‘If there is warping, we can warp the target geometry to arrive at the correct net shape. The benefit of simulations is that you can slow down the process and hopefully that informs you as to mitigations for the mechanisms you see as the cause of the failure.’

Widespread adoption

Combining the physics models with data-mining technologies and uncertainty analyses could also optimize metal parts without the cost of multiple experiments, and aid in more widespread adoption of metal 3D printing, the researchers said.

‘These models will be a big step forward toward getting away from the experience base and getting the science base behind it,’ King said. ‘We’re talking about getting to the place of saying ‘just press print’ for metal. It could broadly impact the way people apply metal additive manufacturing.’

This story uses material from LLNL, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.