Renishaw and UK start-up business Additive Automations have partnered to research automate metal additive manufacturing (AM) post-processing.

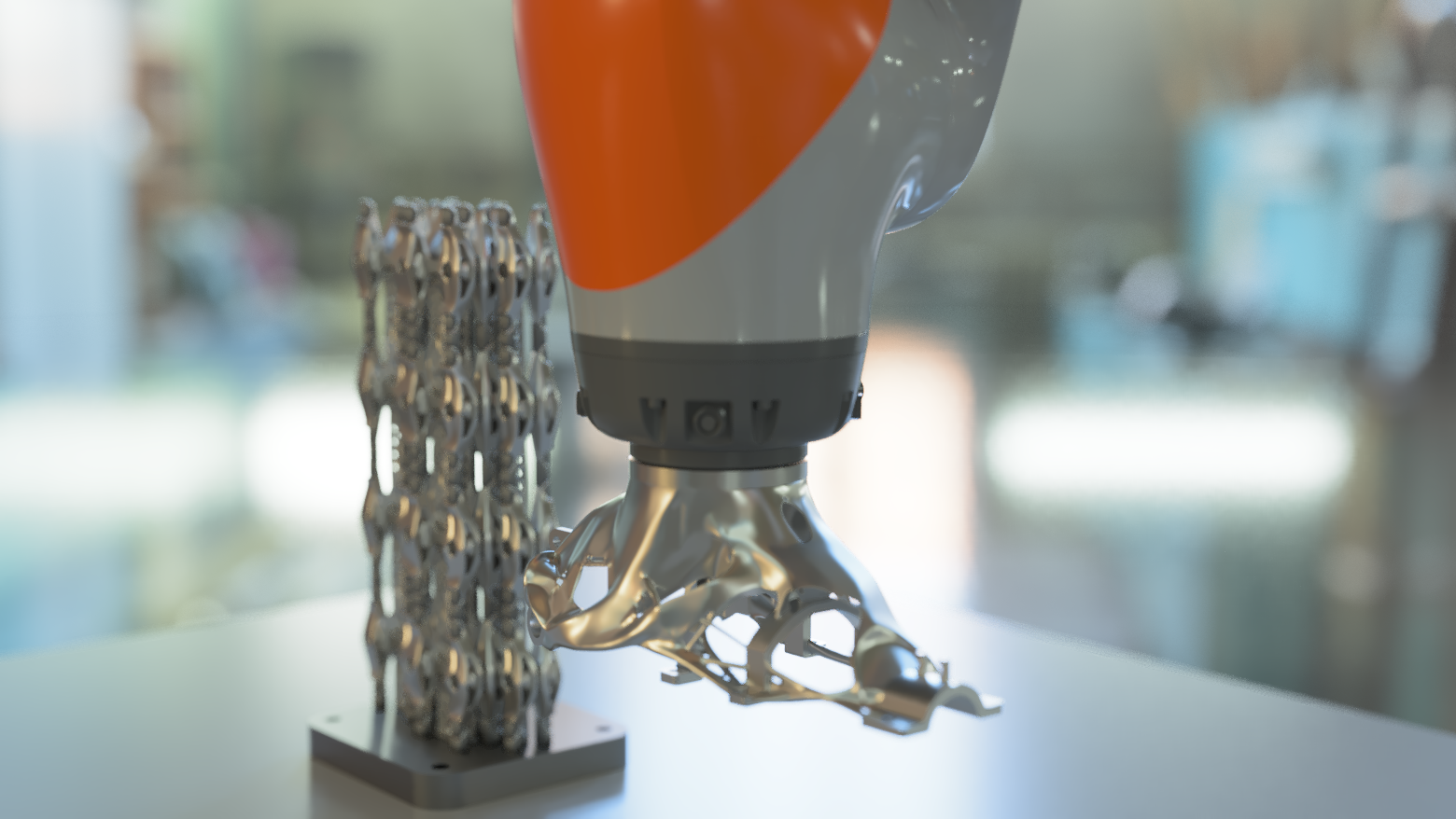

According to the companies, the project, named Separation of Additive-Layer Supports by Automation (SALSA), would involve the use of collaborative robots to perform support structure removal. The process was tested on four examples of AM builds set up Renishaw in order to demonstrate the support structure removal system. The four AM parts were designed for medical, oil and gas, automotive and mechanical engineering applications, Renishaw said.

During the process, the robots used integrated force sensors to collect data to determine the geometry of AM parts. Software then analysed the data, using digital twin technology, and the output is then used to determine where the support structures are so that they can be removed using an end-effector tool.

Renishaw says that the project could reduce the average cost per part by 25%, improving AM's potential as a cost-effective option for large volume production lines.

‘Automating support removal and finishing in AM completely changes the economics when scaling up AM, and for the first time makes it feasible for manufacturers around the world to adopt this technology in rapid production,’ said Robert Bush, founder of Additive Automations. ‘The digitalisation of AM also comes with an increase in quality, traceability and repeatability.’

This story uses material from Renishaw, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.