In turn this could improve productivity and tool life in gear wheel machining operations.

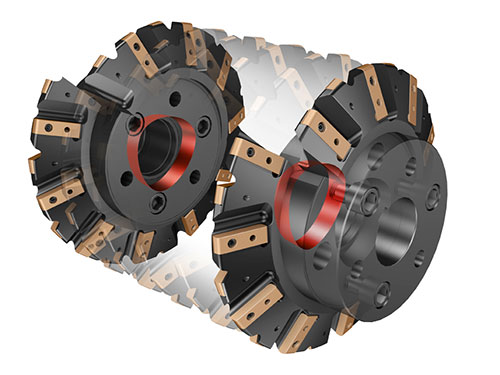

Designed for module range 10-18, CoroMill 177 features indexable carbide inserts with four cutting edges for roughing, semi-finishing and finishing operations. The tool is aimed at parts that include spur gears and helical gears found in gearboxes and transmissions for wind power and other heavy industry applications. It provides an alternative to HSS hobs and disc cutters in operations where productivity is the focus.

The CoroMill 177 allows higher cutting data (up to 50% more) compared with competitor tools, while modern carbide grades from Sandvik Coromant can handle a higher chip load to deliver a minimum 30% improvement in tool life.

In trials on a 36-tooth, module 16 planetary gear, CoroMill 177 exhibited 67% greater tool life over a comparable competitor tool at identical cutting data. Similarly, another trial on a module 18 planetary gear with 33 teeth, showed a 54% boost in productivity, primarily because the more robust design of CoroMill 177 allowed the feed rate to be increased.