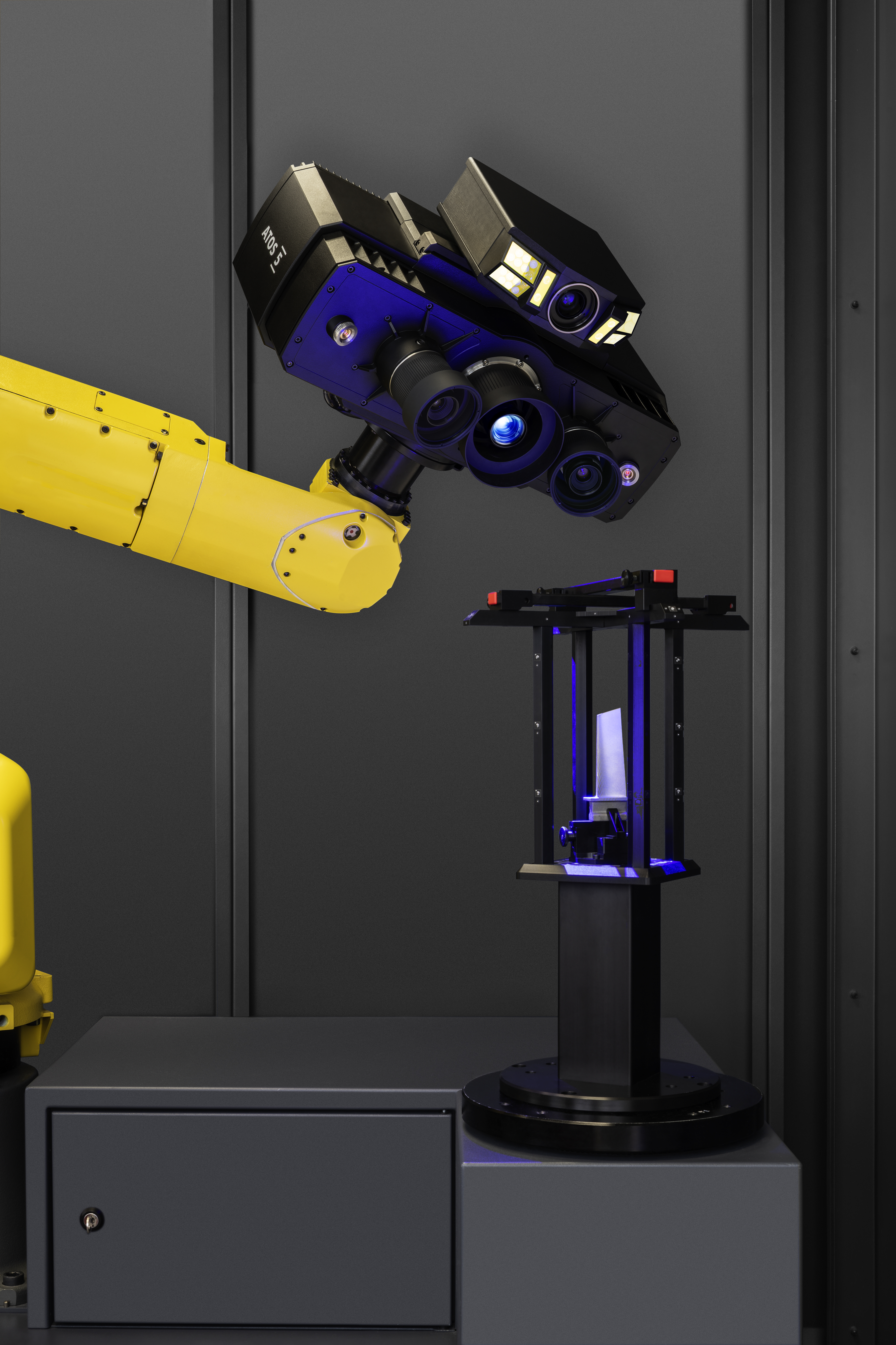

GOM GmbH, which specializes in industrial 3D coordinate metrology, has launched a new optical measuring machine designed for small parts and complex freeform surfaces. The sensor can be used to inspect airfoil components such as turbine blades, nozzle guide vanes or blisks in the aerospace and power generation industries. It can measure small parts with a size of 100 x 70 mm2 to 400 x 300 mm2.

GOM says that it has also developed a corresponding software update. According to the company, its ATOS 5 scanners can scan in one measuring position within only 0.2 seconds, and a total of 120 images per second can be triggered. The measuring systems are also suitable for use in harsh industrial environments.

This story uses material from GOM, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.