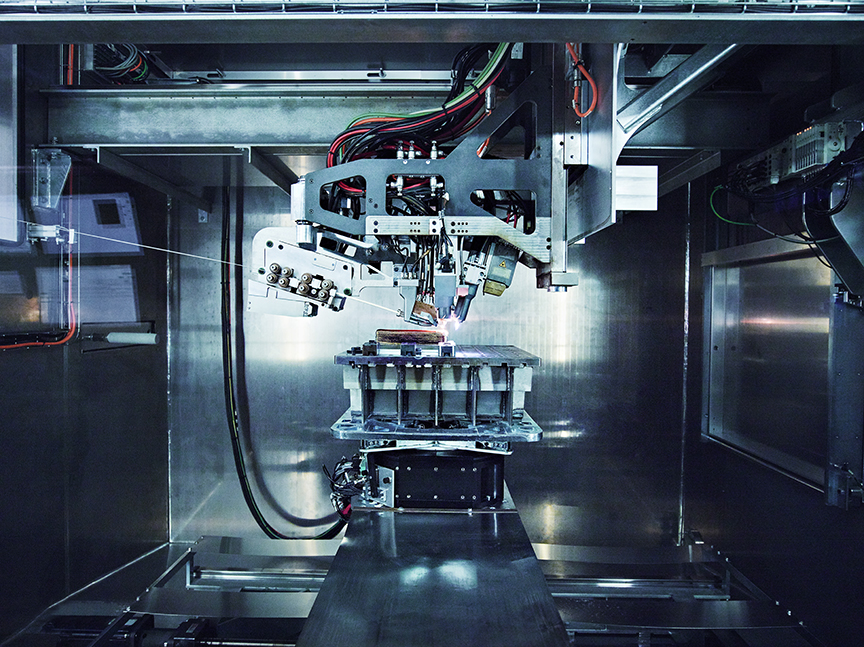

Norsk Titanium AS, which 3D prints structural titanium components, has received an order for additive manufactured (AM) structural titanium components produced by Norsk’s rapid plasma deposition (RPD) process for the Dreamliner aircraft.

‘The Norsk Titanium team will continue to expand the portfolio of components supplied to Boeing meeting stringent certification requirements,’ said Norsk Titanium president and chief executive officer Warren M. Boley Jr ‘It is an honor to earn FAA approval for these structural parts.’

To certify the initial structural components on the Dreamliner, Boeing and Norsk Titanium undertook a testing program with FAA certification deliverables completed in February 2017. Norsk Titanium is the first supplier for Boeing’s high deposition rate material specification.

This story uses material from Norsk Titanium,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.