Manufacturing researchers at the National Institute of Standards and Technology (NIST) have set out new guidelines for powder bed fusion additive manufacturing (AM).

The new NIST report identifies the various key unknowns that must be solved before the technique can progress from largely a ‘trial-and-error’ method to one that can be fine-tuned automatically, according to the organisation.

The report links process inputs to in-process phenomena that might either be measured or modeled and to the ultimate determinants of part quality such as material characteristics, dimensional accuracy and surface roughness.

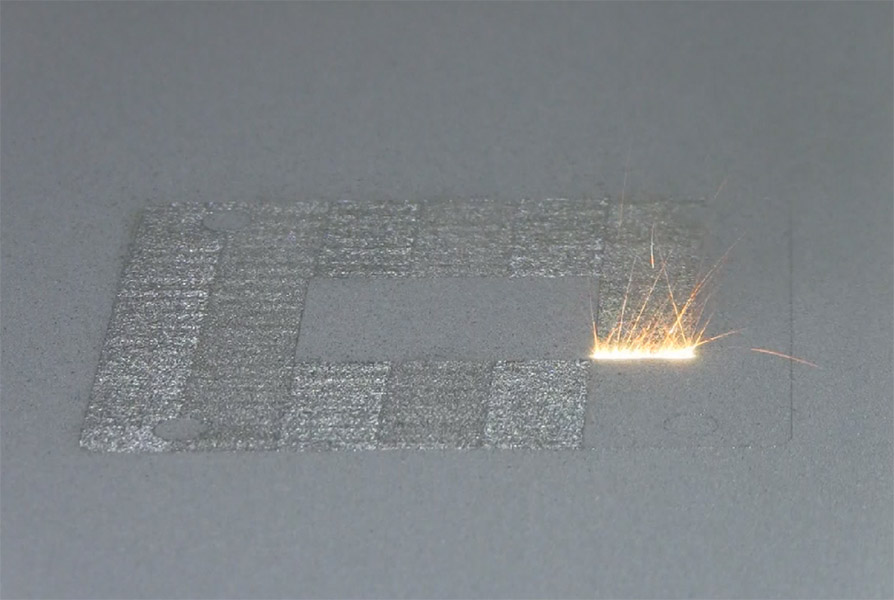

One of seven categories of additive manufacturing processes (as defined by an ASTM standard), powder bed fusion usually employs a laser to selectively heat, melt and fuse the thin top layer of metal particles on a bed of powder. Once a layer is completed, more powder is spread on top and the process is repeated until accumulated layers comprise the designed part. Products ranging from medical implants to fuel nozzles for jets already are made with the process.

Reliability issues

Powder bed fusion, like other additive manufacturing approaches, offers several advantages over conventional manufacturing methods, which often entail removing, or machining, portions from a blank of starting material and usually require joining several machined pieces to build a functional part or product. Although the build process can be slow for metal parts, additive manufacturing is easily customized to make parts with far more complex shapes and features, enabling innovation in design. Parts can be designed to be significantly lighter with the same functionality, and scraps of leftover material are minimal.

However, powder bed fusion of metal parts is beset by system performance and reliability issues that can undermine part quality, problems shared by other additive manufacturing methods. These issues include are dimensional and form errors, unwanted voids in the fused layers, high residual stress in the final parts, and poorly understood material properties such as hardness and strength.

Robust process control through in-process sensing and real-time control can prevent or correct these problems, but achieving this solution requires detailed understanding of all of the many intricacies of powder bed fusion, according to the NIST researchers.

The report sets out 12 categories of ‘process parameters,’ 15 types of ‘process signatures,’ and six categories of ‘product qualities.’ They then chart the cause-and-effect relationships among variables in each of the three categories.

‘This cause-and-effect breakout can guide research to develop measurement and sensing capabilities as well as modeling and simulation tools – all with the aim of enabling better process control,’ says NIST mechanical engineer Brandon Lane, one of the report's authors.

The NIST research team next plans to build an AM test bed to evaluate in-process measurement and control methods. This tool, the report says, will enable the researchers to ‘observe melting and solidification of metal powders, integrate process metrology tools, and implement software interfaces and data acquisition for process measurements, as well as test control algorithms.’

The report is available here (pdf).

This story is reprinted from material from NIST, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.