3D printing company VELO3D has reportedly qualified Hastelloy X nickel-based alloy for its range of additive manufacturing (AM) machines.

The alloy is reportedly suitable for laser powder-bed fusion (LPBF) process and is resistant to corrosion cracking and oxidation. Hastelloy X is most often used to manufacture parts for gas turbine engines for combustion-zone components due to its high temperature strength, the company said.

‘Power generation applications such as industrial gas turbines are a key focus for VELO3D so it is important that we qualify the right materials to serve that market,’ said Benny Buller, CEO. ‘We will continue to add more of these types of compatible materials that enable customers to print parts they couldn’t before.’

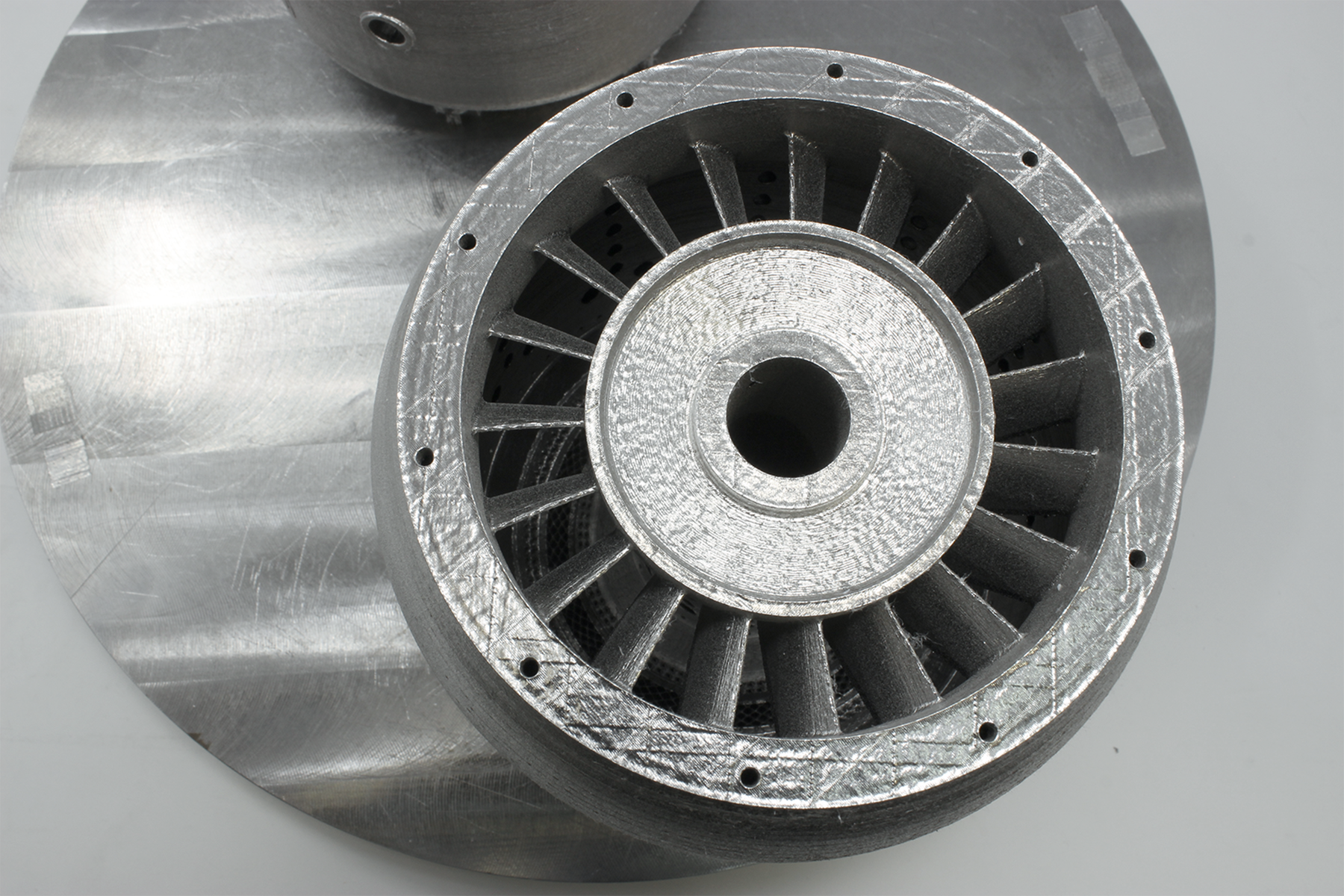

The company says that it recently partnered with power generation company Sierra Turbines to print a prototype of a 20-kilowatt microturbine engine with a unicore in Hastelloy X, aiming to print 95% of the engine through metal AM.

This story uses material from VELO3D, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.