A new study by researchers at McGill University in Canada suggests that metal powders produced using clean primary energy sources could provide a more viable long-term replacement for fossil fuels than other alternatives such as hydrogen, biofuels or batteries.

According to the researchers, relatively little research has been done in recent decades on the properties of metal flames, and the potential for metal powders to be used as a recyclable fuel in a wide range of applications has been overlooked.

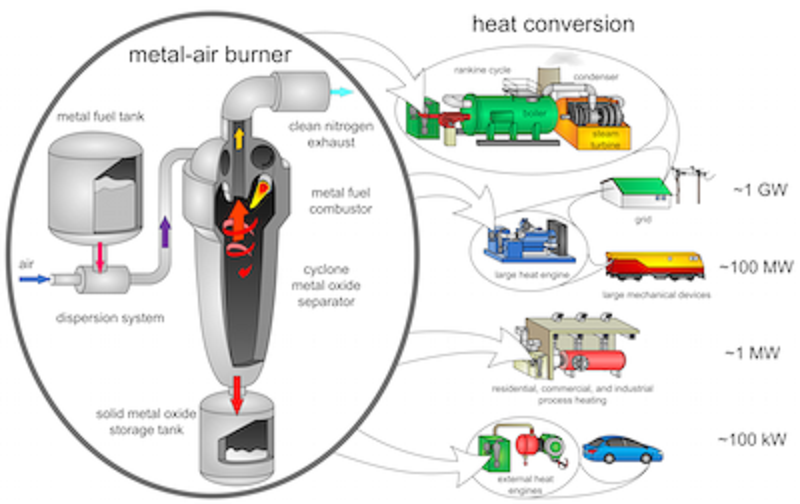

The paper, co-authored by Professor Jeffrey Bergthorson with five other McGill researchers and a European Space Agency scientist in the Netherlands, discusses uses powder metal (PM) similar in size to fine flour or icing sugar to power external-combustion engines. External-combustion engines use heat from an outside source to drive an engine and are widely used to generate power from nuclear, coal or biomass fuels in power stations.

‘Technologies to generate clean electricity – primarily solar and wind power – are being developed rapidly; but we can’t use that electricity for many of the things that oil and gas are used for today, such as transportation and global energy trade,’ said Bergthorson. ‘Biofuels can be part of the solution, but won’t be able to satisfy all the demand; hydrogen requires big, heavy fuel tanks and is explosive, and batteries are too bulky and don’t store enough energy for many applications. Using metal powders as recyclable fuels that store clean primary energy for later use is a very promising alternative solution.’

Attractive technology

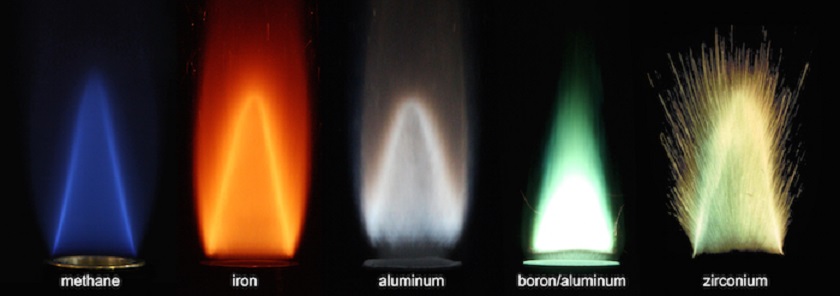

According to the research team, when PM burns, it reacts with air to form stable, nontoxic solid-oxide products that can be collected relatively easily for recycling. Using a custom-built burner, the McGill researchers demonstrated that a flame can be stabilized in a flow of tiny metal particles suspended in air. Flames from metal powders ‘appear quite similar’ to those produced by burning hydrocarbon fuels, the researchers write. ‘The energy and power densities of the proposed metal-fueled heat engines are predicted to be close to current fossil-fueled internal combustion engines, making them an attractive technology for a future low-carbon society,’ they said in the study published in the Applied Energy journal.

Iron could be the primary candidate for this purpose, according to the study. Millions of tons of iron powders are already produced annually for the metallurgy, chemical and electronic industries. And iron is recyclable with well-established technologies, and some novel techniques can avoid the carbon dioxide emissions associated with traditional iron production using coal.

However, while laboratory work at McGill and elsewhere has shown that the use of metal fuels with heat engines is technically feasible, no one has yet demonstrated the idea in practice. The next step toward turning the lab findings into usable technology, therefore, will be ‘to build a prototype burner and couple it to a heat engine,’ Bergthorson says. ’Developing metal recycling processes that don’t involve CO2 emissions is also critical.’

‘We are very interested in this technology because it opens the door to new propulsion systems that can be used in space and on earth,’ said co-author David Jarvis, head of strategic and emerging technologies at the European Space Agency (ESA). The shift away from fossil fuels for vehicle propulsion is a clear trend for the future. While not perfected and commercialized today, the use of low-cost metallic fuels, like iron powder, is a worthy alternative to petrol and diesel fuels. If we can demonstrate, for the first time, an iron-fueled engine with almost zero CO2 emissions, we believe this would then trigger even more innovation and cost reduction in the near future.’

This story is reprinted from material from McGill, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.