The University of Strathclyde’s Advanced Forming Research Centre (AFRC) has expanded its capabilities following the arrival of four pieces of equipment, including a Carbolite emissivity calibration furnace.

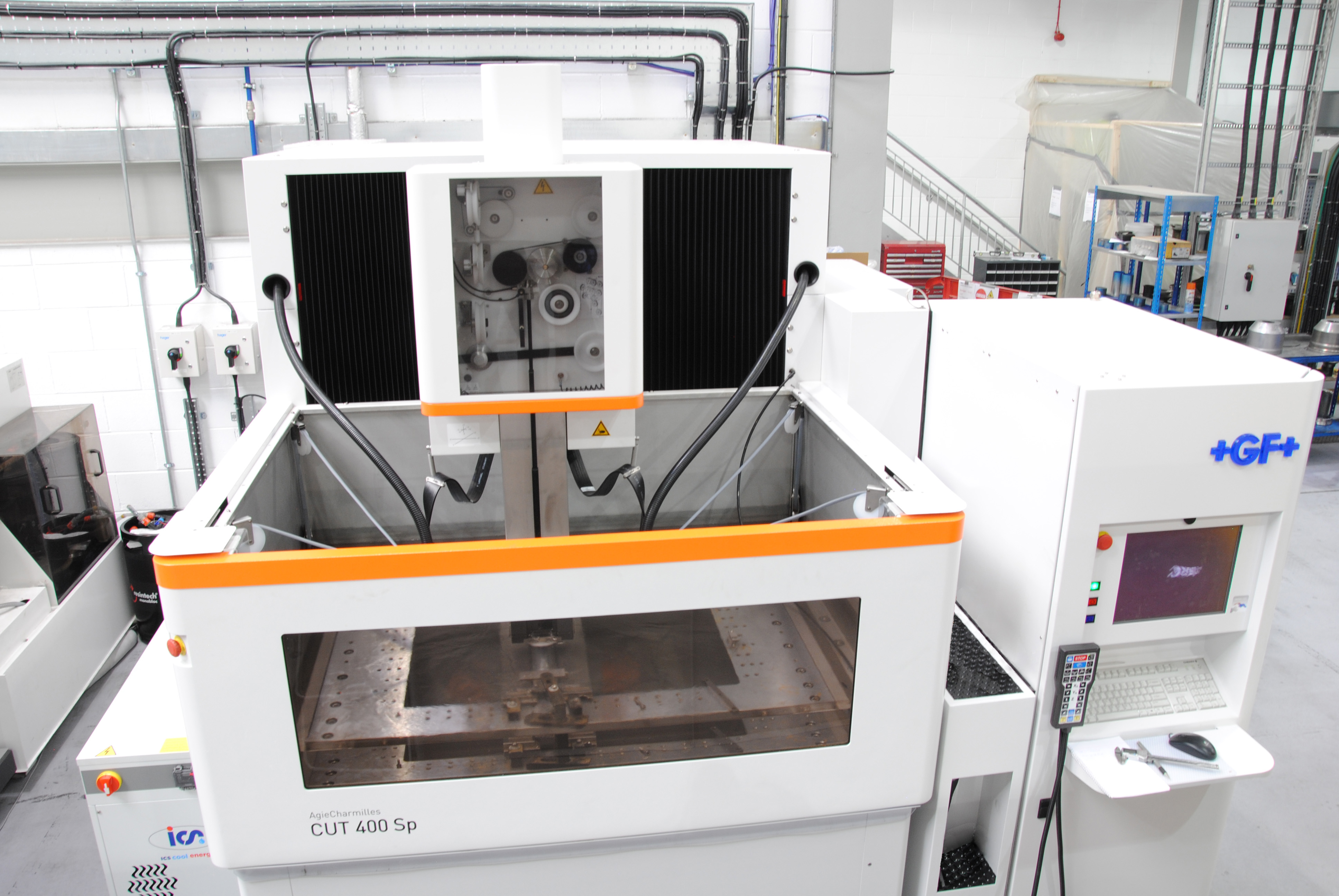

A scanning electron microscope (SEM), a large electrical discharge machine (EDM), an ultrasonic system for residual stress measurement called UltraMars have also been installed.

The emissivity calibration furnace is from Carbolite, a furnace manufacturer who collaborated with the center to produce the bespoke apparatus. Measuring emissivity for numerous ceramic and metallic materials at temperatures ranging from 500 – 1,150oC, the new furnace will allow for more accurate data to be obtained under varying degrees of furnace atmosphere and heat treatment temperature.

The new SEM will allow researchers to examine larger and heavier samples, facilitating more electron backscatter diffraction (EBSD) work.

Equipped with a hot stage, the microscope can perform in-situ thermal experiments up to 1,000°C.

The new EDM and Ultramars have been brought in to support the expansion of the centre’s residual stress offering to customers. The new EDM system is faster than the centre’s original and can cut through much larger pieces of metal – increasing capacity while boosting workload capability. The UltraMars is a portable measurement instrument which can be taken to customers’ premises to carry out in-situ residual stress measurement work.

Overall, this will increase measurement accuracy and control with non-contact infrared thermometers and thermal cameras.

This story is reprinted from material from the AFRC, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.