Nature has worked for eons to perfect surface textures that protect, hide and otherwise help all kinds of creatures survive. There's the shiny, light-scattering texture of blue morpho butterfly wings, the rough, drag-reducing texture of shark skin and the sticky, yet water-repelling texture of rose petals.

But how to use those natural textures and properties in the engineered world? Could the water-repelling, ultrahydrophobic texture of a lotus plant somehow be applied to an aircraft wing as an anti-icing device? Previous attempts have involved molding polymers and other soft materials, or etching patterns on hard materials that lacked accuracy and relied on expensive equipment. But what about making inexpensive, molded metallic biostructures?

Martin Thuo and the students in his research group at Iowa State University have now found a way to make such biostructures. This novel molding technology has come out of their pursuit of 'frugal science/innovation', what Thuo describes as "the ability to minimize cost and complexity while providing efficient solutions to better the human conditions".

For this project, Thou and his group took their previous development of liquid metal particles and used them to make perfectly molded metallic versions of natural surfaces, including a rose petal. They could do this without heat or pressure, and without damaging the petal.

They report the technology, which they're calling BIOMAP, in a paper in Angewandte Chemie International Edition. Thuo, an associate professor of materials science and engineering with a courtesy appointment in electrical and computer engineering, is the corresponding author of the paper.

"This project comes from an observation that nature has a lot of beautiful things it does," Thuo said. "The lotus plant, for example, lives in water but doesn't get wet. We like those structures, but we've only been able to mimic them with soft materials, we wanted to use metal."

Key to the new technology are microscale particles of undercooled liquid metal, originally developed for heat-free soldering. The particles are created when tiny droplets of metal (in this case, Field's metal, an alloy of bismuth, indium and tin) are exposed to oxygen. This results in them being coated with an oxidation layer that traps the metal inside in a liquid state, even at room temperature.

The BIOMAP process uses particles of varying sizes, all of them just a few millionths of a meter in diameter. When applied to a surface, the particles cover it and form-fit any crevices, gaps and patterns through the autonomous processes of self-filtration, capillary pressure and evaporation.

A chemical trigger then causes the particles to merge with each other, rather than with the surface, and solidify, producing a solid metallic replica that can be lifted off to yield a negative relief of the surface texture. Positive reliefs can be made by using the negative replica to create a new mold and then repeating the BIOMAP process.

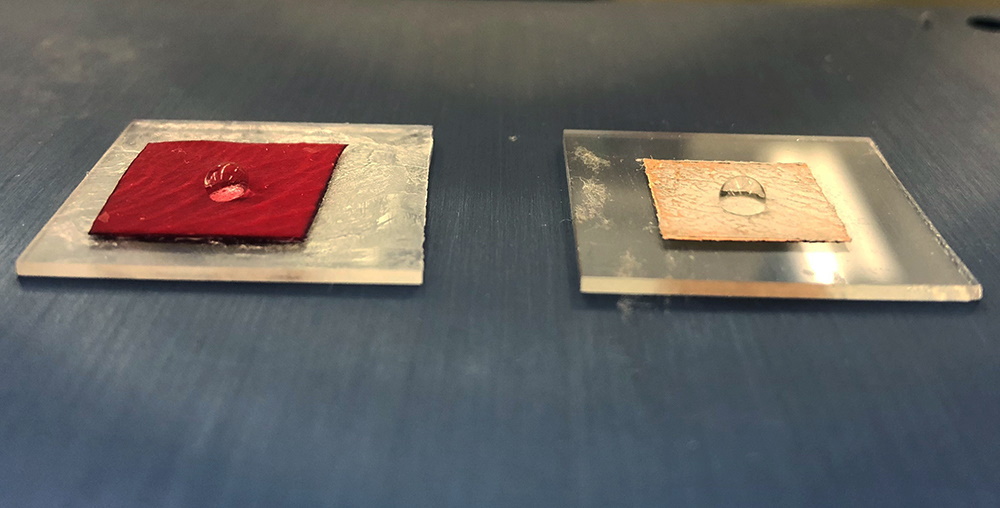

"You lift it off, it looks exactly the same," Thuo said, noting that the engineers could identify different cultivars or roses through subtle differences in the metallic replicas of their textures. Importantly, the replicas kept the physical properties of the surfaces, just like in elastomer-based soft lithography.

"The metal structure maintains those ultrahydrophobic properties – exactly like a lotus plant or a rose petal," Thuo said. "Put a droplet of water on a metal rose petal, and the droplet sticks, but on a metal lotus leaf it just flows off." Those properties could be applied to airplane wings for better de-icing or to improve heat transfer in air conditioning systems.

That's how a little frugal innovation "can mold the delicate structures of a rose petal into a solid metal structure," Thuo said. "This is a method that we hope will lead to new approaches of making metallic surfaces that are hydrophobic based on the structure and not the coatings on the metal."

This story is adapted from material from Iowa State University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.