Researchers from Californian universities have developed and tested a type of steel alloy which could withstand an impact without deforming permanently.

The team, from the University of California, San Diego, the University of Southern California and the California Institute of Technology, say that the alloy could be used in a wide range of applications, from drill bits and body armor for soldiers to meteor-resistant casings for satellites.

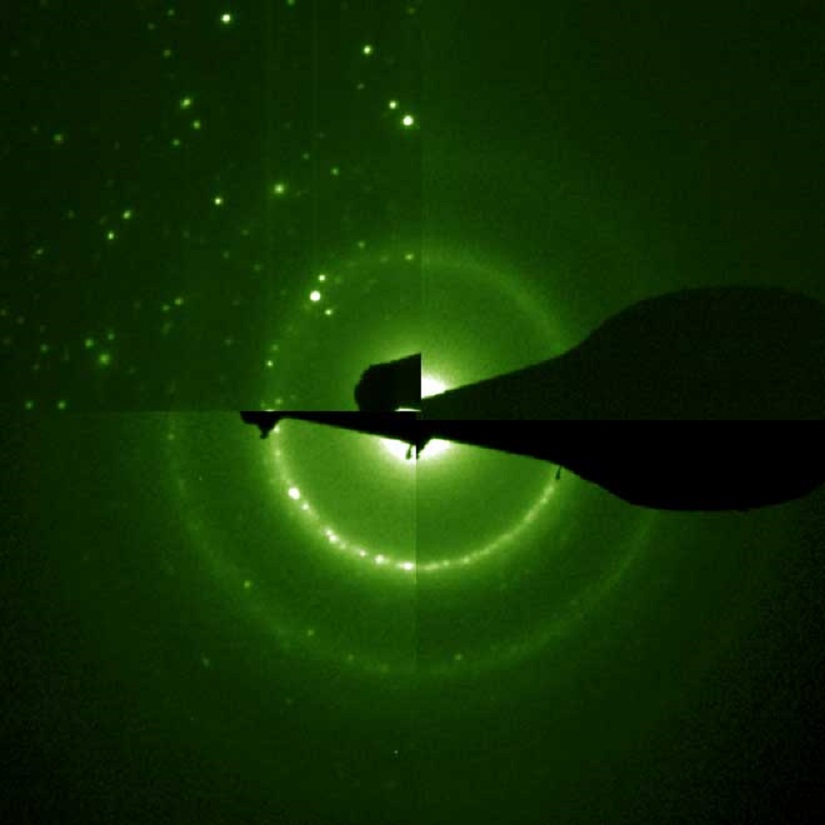

To make the solid materials that comprise the alloy, the researchers mixed metal powders in a graphite mold. The powders were then pressurized at 100 mega-Pascals, or 1000 atmospheres, and exposed to a powerful current of 10,000 Ampers at 1165°F (630°C) during spark plasma sintering.

The material is an amorphous steel alloy, a subclass of steel alloys made of arrangements of atoms that deviate from steel’s classical crystal-like structure, where iron atoms occupy specific locations.

Researchers are increasingly looking to amorphous steel as a source of new materials that are affordable to manufacture, hard and not brittle, the universities say. The researchers believe their work on the steel alloy, named SAM2X5-630, is the first to investigate how amorphous steels respond to shock. The alloy has the highest recorded elastic limit for any steel alloy, according to the researchers, the highest threshold at which the material can withstand an impact without deforming permanently. The alloy can withstand pressure and stress of up to 12.5 giga-Pascals or about 125,000 atmospheres without undergoing permanent deformations.

‘Because these materials are designed to withstand extreme conditions, you can process them under extreme conditions successfully,’ said Olivia Graeve, a professor of mechanical engineering at the Jacobs School of Engineering at UC San Diego, who led the design and fabrication effort.

Overcoming brittleness

The spark plasma sintering process created small crystalline regions that are only a few nanometers in size, with hints of structure, which researchers believe are key to the material’s ability to withstand stress. This finding is promising because it shows that the properties of these types of metallic glasses can be fine-tuned to overcome shortcomings such as brittleness, which have prevented them from becoming commercially applicable on a large scale, according to Veronica Eliasson, an assistant professor at USC, who led the testing efforts.

Researchers at USC tested how the alloy responds to shock without undergoing permanent deformations by hitting samples of the material with copper plates fired from a gas gun at 500 to 1300 meters per second. The material did deform on impact, but not permanently. The Hugoniot Elastic Limit (the maximum shock a material can take without irreversibly deforming) of a 1.5-1.8 mm-thick piece of SAM2X5-630 was measured at 11.76 ± 1.26 giga-Pascals.

By comparison, stainless steel has an elastic limit of 0.2 giga-Pascals, while that of tungsten carbide (a high-strength ceramic used in military armor) is 4.5 giga-Pascals. ‘The fact that the new materials performed so well under shock loading was very encouraging and should lead to plenty of future research opportunities,’ said Eliasson.

The primary focus of future research efforts on these alloys is increasing the weight of the materials to make them more resistant to impacts, the researchers conclude.

This story uses material from The University of California, San Diego, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.