Aurora Labs has set up a Kickstarter project to finance its project to develop the world's first affordable 3D metal printer.

According to the Kickstarter page, those who pledge US$4,499 or more, will receive an early adopter S1 3D printer and 5kg of 316 stainless steel plus shipping.

However, the final retail price will not be reflective of the Kickstarter price, the creators say.

The S1 is one of three 3D metal printers offered by the company, who claims that it can print multiple metals (including 316 stainless steel, 420 stainless steel, Inconel 625, Inconel 718, Hastelloy C, brass, bronze and mild steel) at the same time and potentially ceramics and plastics as well.

Besides the S1, the company also offers the S2 multiple metal printer with a build area of 150mm x 150mm x 200mm and three powder feeders, the S2+ large bed printer with a build area of 180mm x 180mm x 500mm and the S-T large bed titanium printer with a build area of 180mm x 180mm x 500mm.

Mass market

“This new machine has been made possible by breakthroughs in new technology and innovations in design as well as gearing production towards a mass market,” said Aurora Labs on its Kickstarter page. “With this machine people can build a 10,000 pound (4,500 kg) thrust rocket motor – for about the price of a plasma TV (US$500-US$1,000) in materials.

“We have done most of our work with 316 – stainless steel and nickel based alloys. However, due to our technical experiencing in welding and cladding processes, we are comfortable that the printer will be able to print with all materials listed in the product specifications,” the company added.

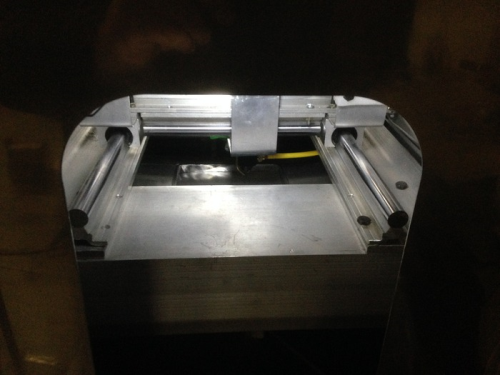

The control system for the printer feeds power to a motor at a controlled speed, and powder is propelled into the high energy beam. Once fed, it is then melted and fused with substrate – the base material. The build area requires an inert gas, and depending on the materials you are building with, either nitrogen or argon can be used. The entire system is sealed and there is scrubbing system that reduces the gas consumption and keeps oxygen levels down.

In July, another start up company Matterfab launched its own cheaper 3D metal printer.