Researchers at Carnegie Mellon University have developed a new microscopy technique that they say shows the limitations of established material prediction models.

According to the university, the technique using near-field high energy diffraction microscopy (HEDM) showed that the established model for predicting a material’s microstructure and properties does not apply to polycrystalline materials, and a new model is needed.

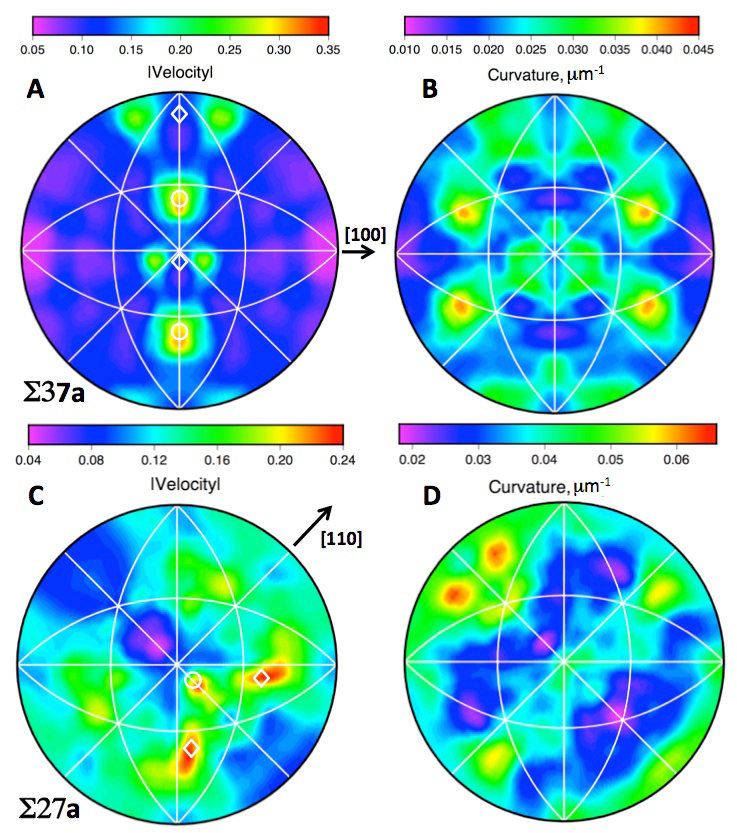

Previously, researchers have predicted material behavior by analysing the speed at which grain boundaries move throughout a heated material is correlated to the boundary’s shape. However, the Carnegie Mellon research says that this does not apply in real polycrystals.

‘A single grain boundary in a crystal can move without interruption,’ said Gregory Rohrer, professor, materials science & engineering. ‘In polycrystals movement is like hitting traffic—it can’t move so freely and so the model no longer holds.’

While the researchers’ current analysis is based on a single material (nickel) they believe that other materials will demonstrate similar behavior.

This story uses material from Carnegie Mellon, with editorial changes made by Materials Today.