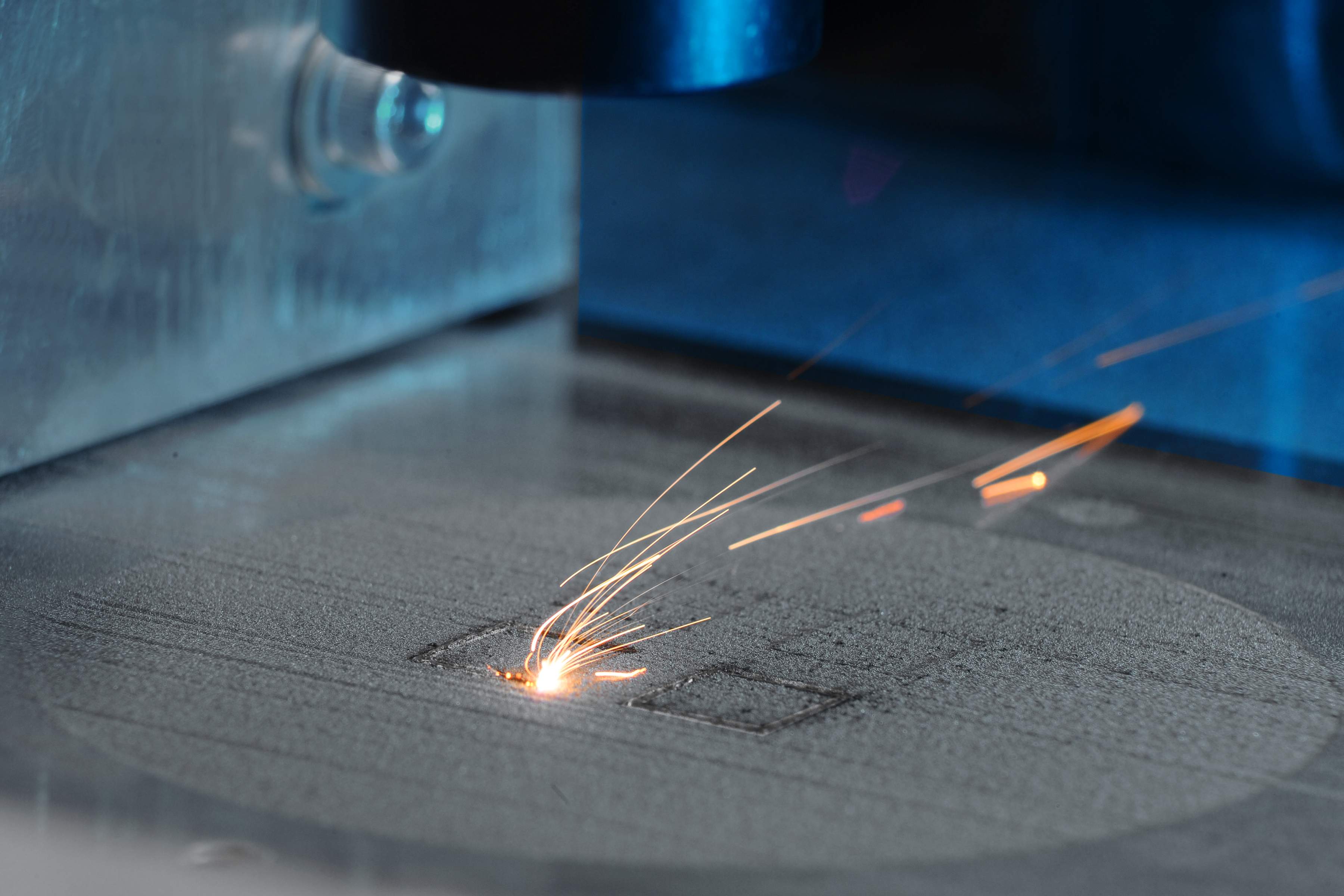

The Aachen Center for 3D Printing and the Fraunhofer Institute for Laser Technology has developed a low cost unit for selective laser melting (SLM). The unit is intended primarily for small and medium-sized enterprises (SMEs) for whom expensive selective laser melting technology is not yet economically viable because of the high level of investment required.

‘Our group of experts works closely together to give medium-sized companies access to 3D printing,’ said the director of the center, professor Gebhardt. The new center also offers companies additive manufacturing (AM) training courses, advice, and services covering component design, manufacturing, and finishing processes.

The first functional prototype employs a Cartesian coordinate system and uses a 140 W laser diode with a focus diameter of 250 µm to produce metal components with a maximum height of 90 mm.

While a unit with a comparable installation space could cost around €100,000 euros, the low-cost SLM unit will have a price tag of €30,000, according to Dawid Ziebura, a project engineer at Fraunhofer ILT. Entry-level users need only a few hours to learn how to operate it, and that it is easy to use. All of the components in the unit allow users to maintain the unit themselves, and are easy to replace, the organizations say. ‘The low-cost unit makes it easy for entry-level users getting into 3D printing of metal components,’ Ziebura adds.

Construction time

The components that the unit can produce are suitable for many SLM applications, ranging from prototypes and sample parts to functional components. Users themselves decide the speed and the production quality at which the unit operates. It can, for instance, produce a medium-sized (55 cm³), stainless steel part (grade 1.4404) at a density of more than 99.5% within 12 hours. In addition, the unit offers the option of producing lattice structures for large-volume areas in order to shorten the construction time of less stressed areas. Selecting a lattice density of 20% (corresponding to 20% of the original volume) reduces construction time by 60%.

This story is reprinted from material from Fraunhofer, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.