Rodin Cars, a New Zealand-based automotive manufacturer, has used a 3D printer to produce parts for its FZero racing car.

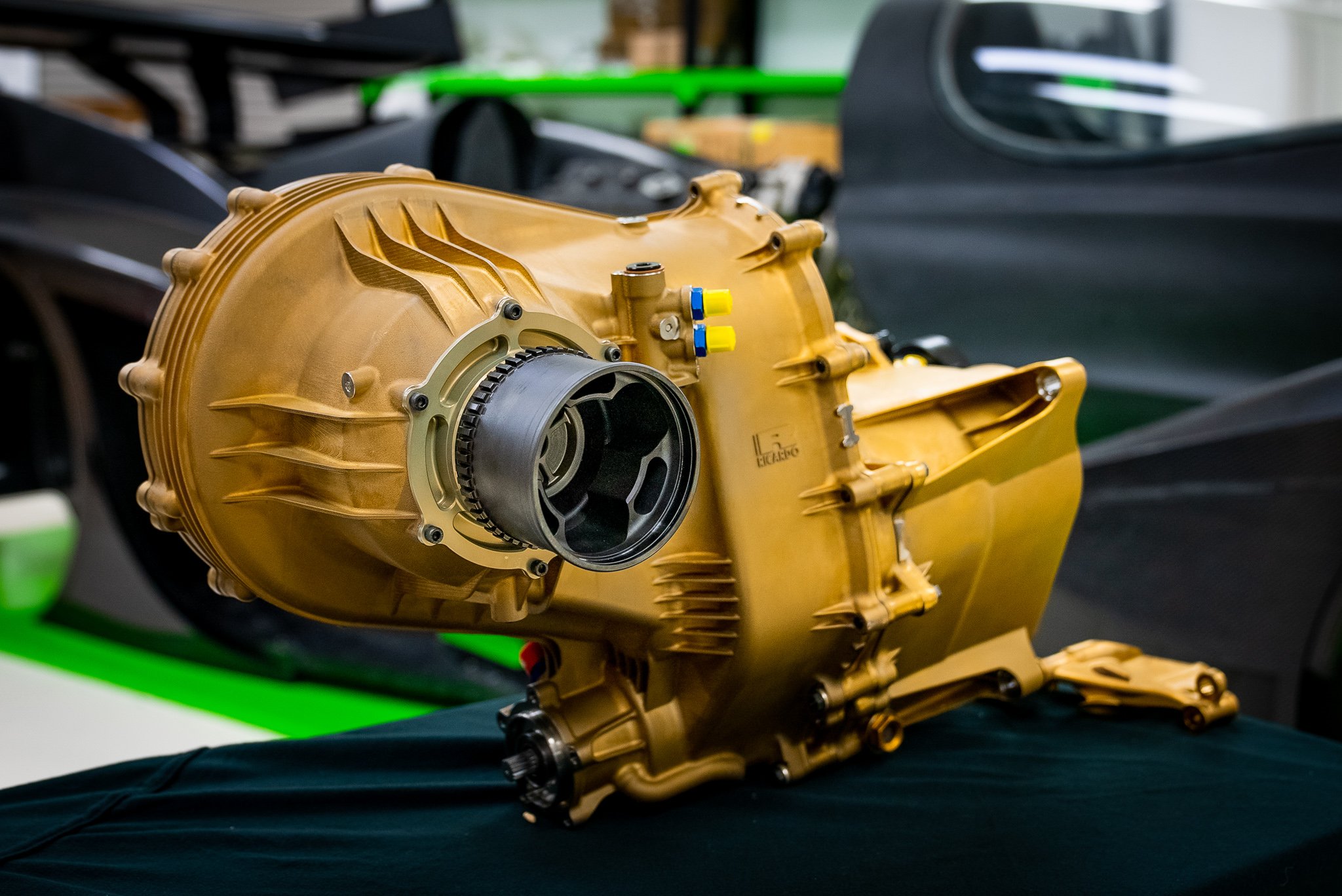

The single-seat, open-wheel vehicles is said to be faster than contemporary Formula 1 cars and features a custom 3D printed eight-speed sequential gearbox with a hydraulically controlled differential.

According to 3D Systems, a gearbox created using traditional manufacturing methods would have to be cast out of magnesium or machined from billet material. The resulting component would slower to produce and too heavy to withstand the rigors of the racing track.

Rodin Cars’ component is produced from 3D printed titanium and is reportedly more compact, light, strong, and durable than traditional parts, with 2mm thick walls and a total weight of 68 kg. It features internal galleries and thin wall bearing and mount structures only possible using addi-tive manufacturing (AM), the companies say.

‘3D printing allows us to design and create components otherwise unachievable using traditional methods of manufacturing,’ said David Dicker, founder of Rodin Cars. ‘With the Rodin FZERO gearbox, we had specific criteria we wanted to meet in terms of weight and durability. Because of the size and quality required for such a large component, it was only possible to print it on 3D Systems’ DMP Factory 500 machine.’

This story uses material from 3D Systems, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.